Caleb Denton – husband, father, gold miner and bike builder – talks his obstacle-ridden journey to Born Free

Words by Joy Burgess

Photos courtesy of Caleb Denton

It’s not always easy to get ahold of Caleb Denton. The guy spends days at a time underground in actual gold mines. Building custom motorcycles might be his passion, but like many other builders he’s gotta pay the bills and take care of his family. So it’s five days underground in the mines, and then five days off in his home garage working on bikes.

Denton’s been working on motorcycles since he was just a kid and building bikes in shops for years, but it wasn’t until 2018 that he built a bike under his own name. The goal? To get his build into the Biltwell People’s Champ competition held at the Born Free show. It wasn’t easy, and life fought him the whole way. But the gold miner from Nevada didn’t give up, that fighting spirit paid off, and he’s not done bringing badass builds to the custom motorcycle scene.

The Early Years

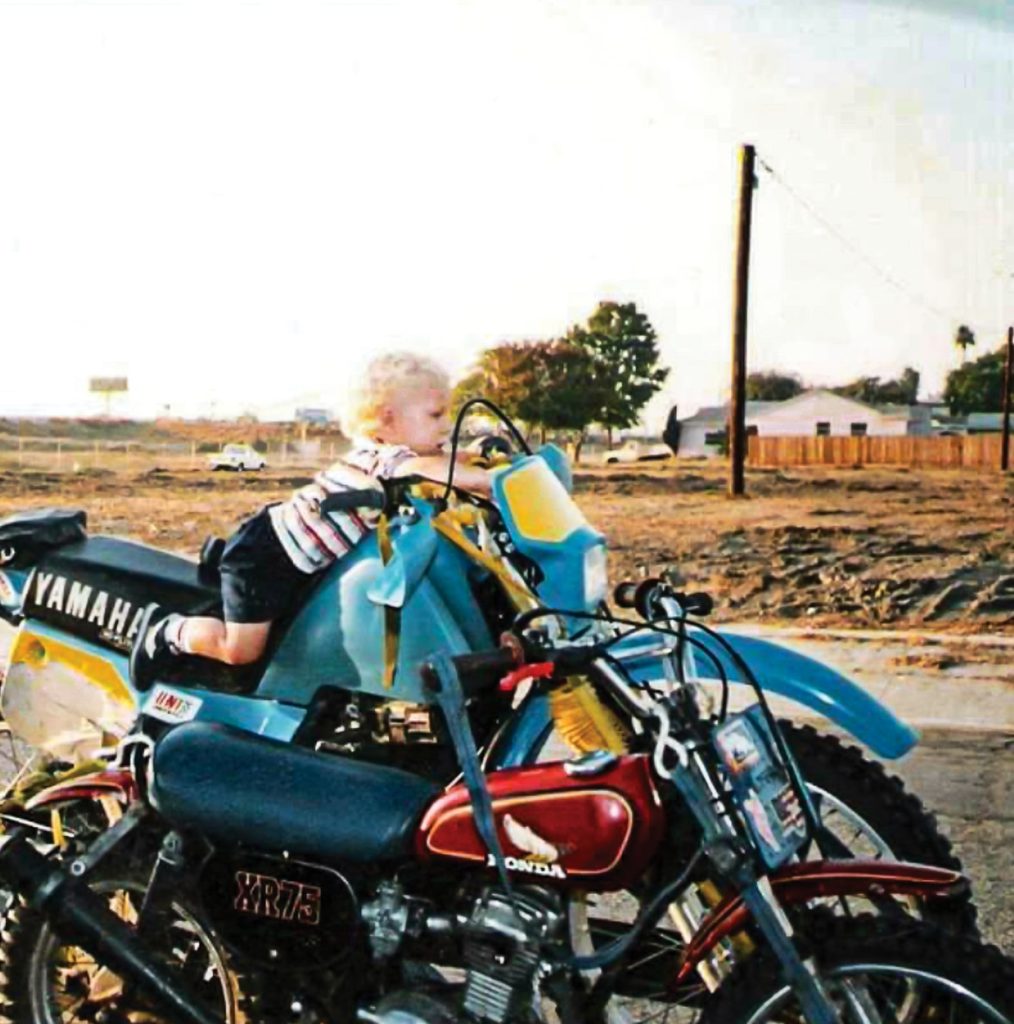

Denton’s dad was a rider, so he grew up around bikes at an early age in California. “My dad has been riding since ’72,” he told us, “so I grew up bungie corded to a sissy bar. And as soon as I could climb up on one, I was off riding and racing dirt bikes.”

Riding bikes wasn’t enough, though. “My dad wasn’t really into building them,” Denton said. “We had a tight budget, so his days off were spent piecing together swap-meet bikes to keep the bikes running, and I’d been sitting in the garage finding out how to make them work and keep them working, too. My parents bought me a ‘basketcase’ when I was about 12 and told me I could have it if I could figure out how to make a bike out of it and pay for my own insurance.”

When he was just a freshman in high school, Denton took pictures of that build to BMF Supercycle in Downey, California, asking for an apprenticeship…and they agreed. While he learned a lot working there and by spending time taking in everything he could at Juan’s Polishing located next door, he wasn’t making enough money, so he got into the gold mining scene and kept building bikes on the side.

Gold Mining Life

Gold mining life isn’t what you’d expect. Workers climb into a cage that holds up to 30 people and are lowered below ground into tunnels called “drifts.” And while every mine is a bit different, these days they’re like an underground city. “We have running water,” Denton told us, “full electricity, big sub stations, shops and fuel stations down there. Framed and dry walled rooms are available for breaks and eating, and the bosses all have offices below ground. Little known fact: there’s actually a mine that had an office once used as a getaway for Bush 41. Sometimes he’d need some time for himself and he could get away down there, packed away in a cave in Nevada to get some work done or just have some time alone.”

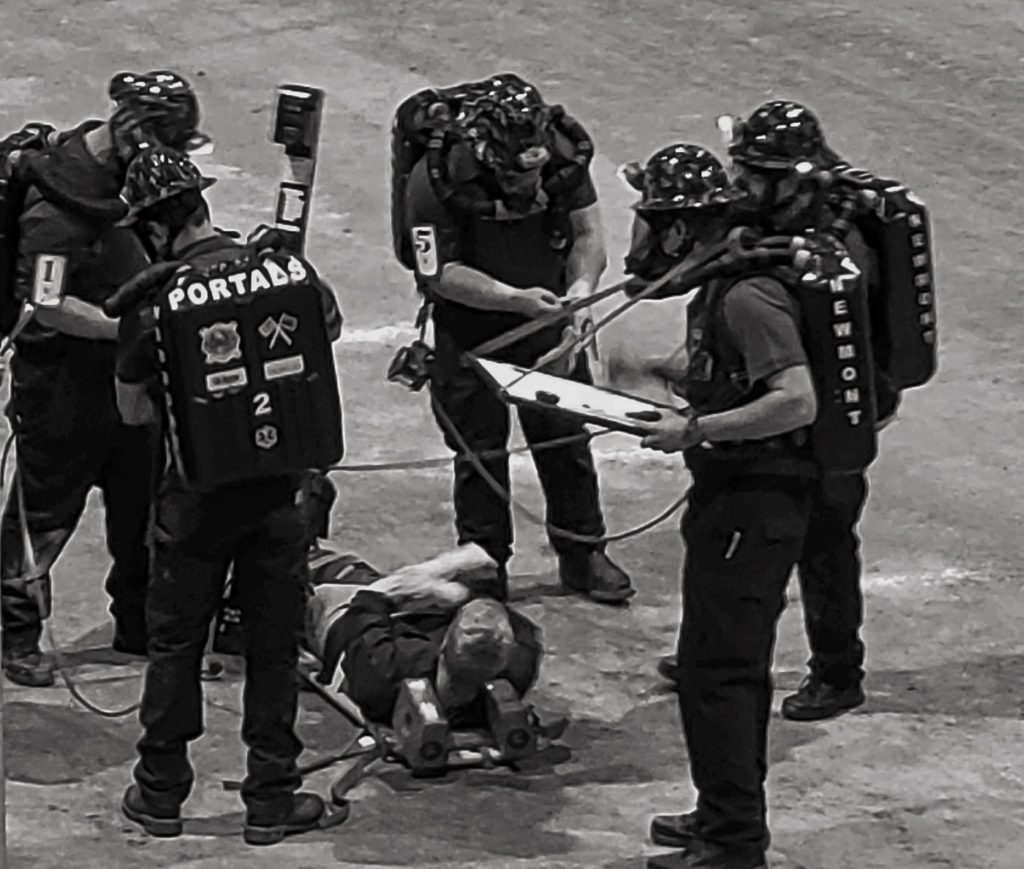

Denton is a field mechanic, which means half his time underground is spent fixing whatever breaks below ground. The other half of the time he’s part of the underground mine-rescue team, the mine’s own ambulance and fire service. “To be allowed in the mines you must have an explosive ordinance handler’s license, mine hazard certificate, and more,” Denton said, “so we have to be able to do it all ourselves underground.” And this includes taking care of their own emergencies.

While his gold mining job pays the bills, it’s also had an impact on his bike builds. “Probably the biggest impact,” he noted, “is the additional training I get through the mines. Obviously, they don’t want mechanics underground that just go around duct taping things together, so they send us to lots of different classes. We get to learn things about equipment from other countries and we’re learning things that most people don’t see, including a lot of interesting electronics training.”

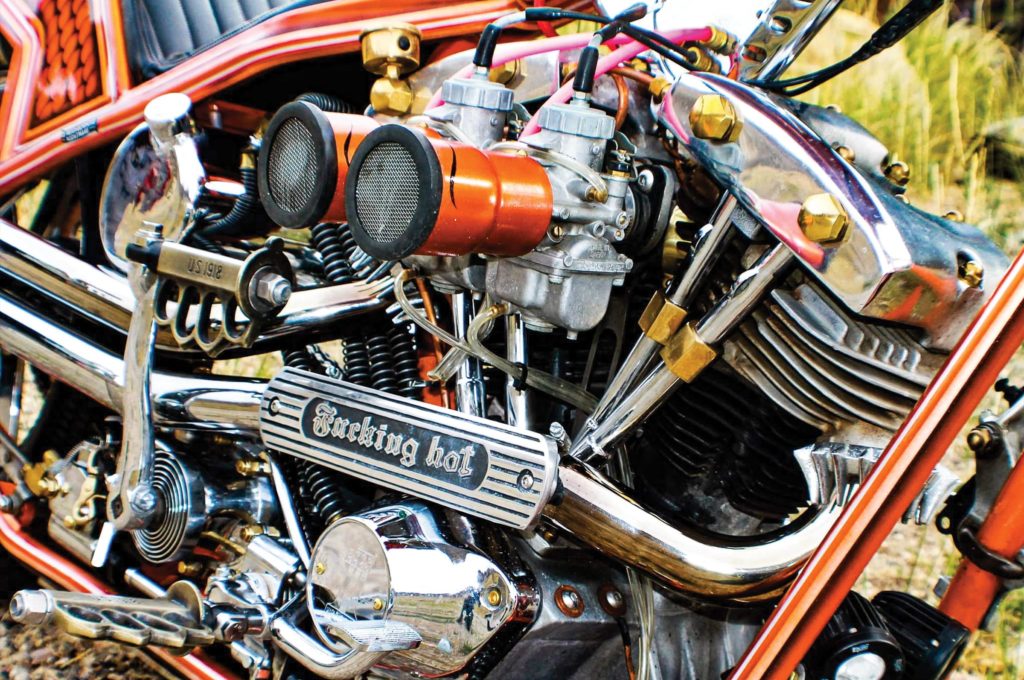

“For many people,” he continued, “choppers are very basic. But for the Shovel build I did, I actually ran it with LEDs inline, so if you have an electrical problem it’ll kick off the LED. You just pull over, under the tranny I have lights that are numbered, and you can see which one is out. I’ve got the license plate held on with wing nuts, so you can see the numbered parts to figure out what went wrong. Sure, it’s still a basic, simple system, but it’s learning how to make complicated stuff simple, and I have the advantage of taking classes and learning this stuff.”

The Journey to Born Free

Denton’s built quite a few show bikes over the years since he first started building bikes in 2001, but it’s always been under another shop’s name. He’s been the guy in the background, and it wasn’t until the 2019 Biltwell People’s Champ rolled around that he finally built a bike under his own name. But it was a long journey getting there.

“I’d been watching the People’s Champ build competition at Born Free for some time,” Denton mentioned, “and I’d planned to do it in 2015.” But his wife was pregnant with twins, and then tragedy struck their family.

“I got the call that Amanda [his wife] had gone into labor,” he told us. “By the time I got there, Rebel Kash was already born and hooked up to machines. A bit later, Remi Faith was born. I could tell that things weren’t going to go in our favor, and soon both of my little girls’ lungs failed. There was nothing we could do but say goodbye.”

After losing their twin girls, Denton decided he just couldn’t do People’s Champ at the time and withdrew his application.

It wasn’t until 2018 that he finally got back to building. “I still had parts I was going to use in the original build back in 2015,” Denton said, “and then my friend’s brother died and he asked me about rebuilding his brother’s bike. We went over a few designs and I said if he’d keep up with the cost of supplies, I’d do the labor free.”

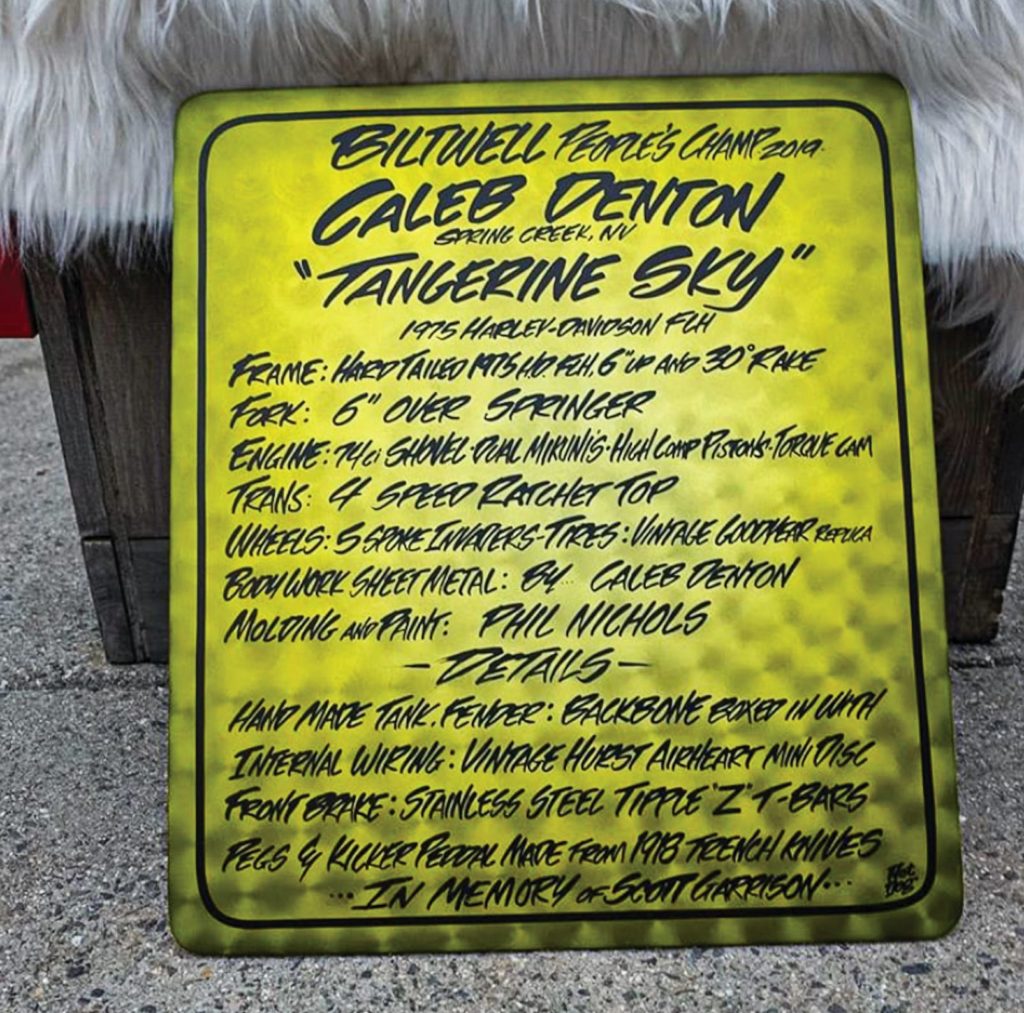

Denton started his “Tangerine Sky” build with a ’75 Harley-Davidson FLH Police Special shovelhead, and once he got into it he found it had been wrecked. “The bike had been T-boned and someone had bonded it up to make it look straight again,” he told us. “There were enough salvageable parts on the frame to keep a clean title, but we had to do major work on it. My friend’s brother was eccentric, so our goal was to keep it rideable but go as wild as we could.”

As the bike took shape, Denton sent in the application for the 2019 Biltwell People’s Champ, but he didn’t get in. “They told me to apply again next year. Out of thousands I was right on the edge of making it, and they only picked 25, so we slowed down a bit on the build.”

After slowing down on the bike, Denton started feeling bored, so he turned to a favorite pastime – skateboarding. “Winter hit,” he said, “and I got bored and built a halfpipe inside my house to skateboard in the winter, and ended up breaking my hand.”

In a crazy twist of fate, just three weeks later two people dropped out of the People’s Champ competition. After his loyal social following started bombarding Biltwell, they asked for pictures and information from him again. “I got an email back,” Denton said, “and they said, ‘You’re in!’”

There were only nine days until the first vote and he had a broken hand. As a TIG welder, that was a problem because he needed both hands to weld. But it didn’t stop him. “I wedged the filler rod into my cast and kept practicing until I had it figured out. When they did that first round of voting, I was on a business trip for work doing a mine rescue competition out in the middle of nowhere. When I finally got to WiFi, I had all these congrats messages and found out I was in the top 13. But the next vote was just four weeks out and I wouldn’t be home for another nine days.”

“Once I got home,” he continued, “I had welds to finish up (with the broken hand), then paint, and I had to get the motor running, which involved a complete transmission rebuild after I found out it’d been blown up.”

With six weeks to go until the bike had to be on stage at Cook’s Corner, Denton had a running, rolling chassis. It was time to think about chrome and making all the parts look good. “I started making phone calls to ship out all my chrome,” he said, “and the soonest I could get chrome back was three months.” Obviously, that wasn’t an option.

“So I had to sit down and brainstorm what I could do with everything I needed chromed,” Denton went on. “In two weeks I put in about 160 hours building everything I needed out of aluminum and stainless, and then it had to be polished. I taught my wife how to polish so she could help, and a friend who’s a fabricator helped me get a few of the parts done. Forty-year-old parts from the ’75 shovel don’t look like brand new chrome, so we stripped everything down and my wife was helping me clean it all. We had parts in the dishwasher, then scrubbed them by hand, and then back in the dishwasher. The kids were taking baths with wheels and scrubbing on parts for me, too. My wife would do all of the prepping, and then I’d finish the polishing process. People don’t realize how much time and effort that type of prep takes.”

That last six weeks was a mad dash, and even once they were in California at the Born Free show Denton was continuing to make last-minute adjustments. “The bike was already on stage at Cook’s Corner and I was up there tightening things at the same time.” And the dual Mikunis taken from a dirt bike needed to be tuned a bit with the change in altitude.

“Pretty much everything that could have gone wrong, did,” Denton told us. “But I was the only one who rode my bike to the show and the only one with a license plate on the bike. I didn’t win, but the bike took third place.”

And Denton’s proud that his bike was one that you can ride. “Many choppers either run a stock frame so the bike handles well or they have a custom frame that you can’t even ride. I hate seeing bikes carried into a show because you can’t even push the bike without messing it up. There’s a pic I took through the handlebars while riding my build, I was doing 110mph and could let go, grab my phone and take a picture. Look closely at the bike and you’ll notice it’s slightly scraped up on the bottom because I can lay it through turns until I’m dragging the pegs on the ground. It handles more like a crotch rocket than a Harley because I wanted to make it high-performance and rideable while still keeping it a chopper.”

While his “Tangerine Sky” build didn’t win the Biltwell People’s Champ, it was still a win for Denton and his family. Out of thousands of entries, he made it to the show despite all the challenges life threw across his path along the way. And it was a high moment when the bike went on to win the six-foot tall “Best in Show” trophy at Rides and Rods just a short time later.

What’s Next?

Denton spent some time working in Attitude Custom Cycles located in Arlen Ness’ Las Vegas dealership, and that had a big impact on him. “I got to see up close some of his personal builds,” Denton said, “and it was interesting seeing what he was doing. Looking at them you could almost climb into his head and see what he was thinking.”

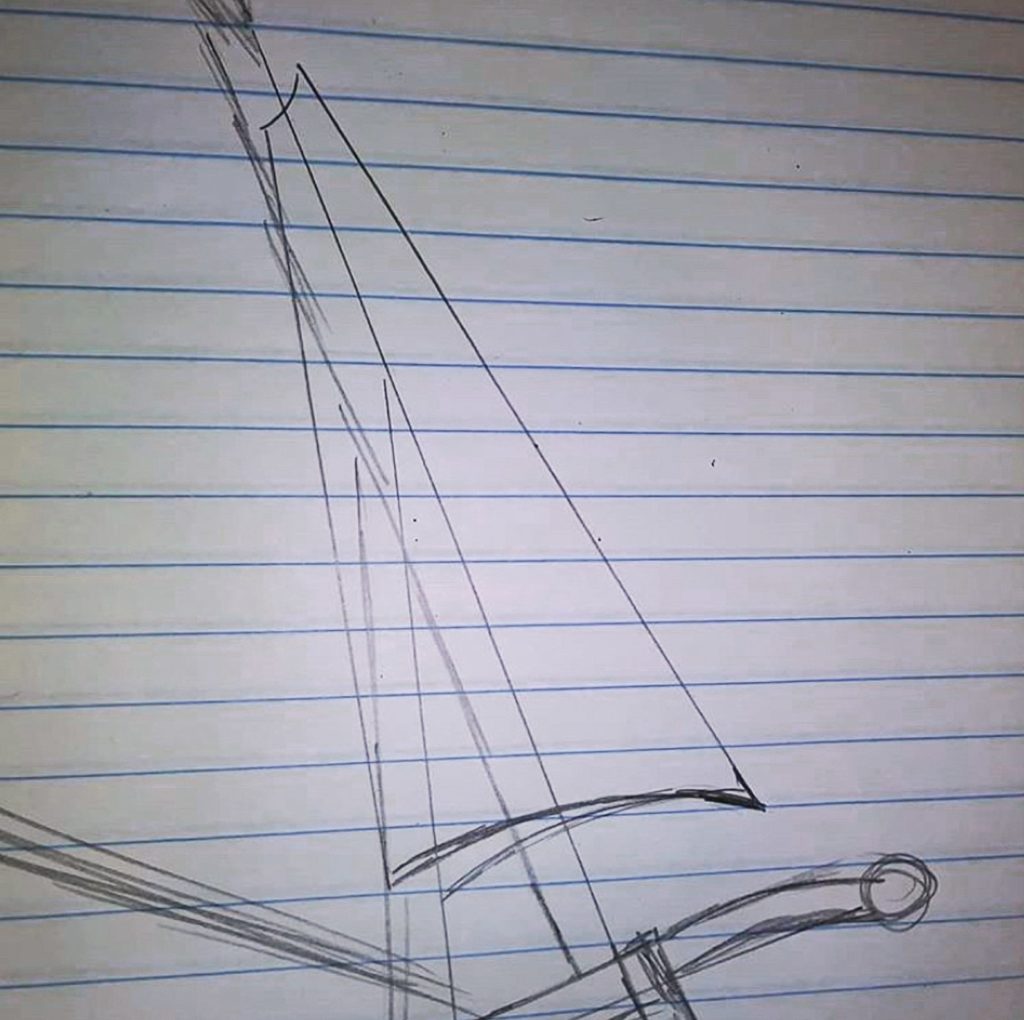

“I’ve had an Arlen Ness frame hanging on the wall for years, he continued, “and since Arlen passed I figured it was time to yank it down and start working on it. Shows today are about 95% Harley, and this Arlen Ness frame is for a CB750, so I’m going to work on something different – a four-cylinder Honda with a twin turbo. The plan is to use a lot of brass. Arlen Ness did a lot of gold plating, and that’s not an option for me, so we’ll do brass instead. Make everything out of steel and then take brass tubing and spin it on a lathe to make it go over the steel, pressing it on top and polishing it out until it looks like gold.”

“Everyone gets inspiration from things they see,” Denton added, and it’s those little inspired touches like the hand-made winged tank, the brass knuckles-turned foot pegs, and the bike’s drag bike-style rear fender that make ‘Tangerine Sky’ stand out. But beyond the bike, it’s Denton’s hard work, perseverance and refusal to give up despite difficult circumstances that make the man stand out.

His goal is to eventually start his own bike building business and leave the mines behind… and he’s on his way. “Although I didn’t hit it big with a jackpot,” he said, “or get a major investor telling me he’ll fund me to drop everything and build bikes, I did catch some of the right attention.” And it doesn’t matter what life throws at him – he’s not done!