Even experts can’t seem to agree on exactly how much power is lost through the not-really-understood interplay between rings, pistons, cylinder walls and oil. Most of ’em seem to hover at guesstimates in the range of 10 to 25 percent. That’s a fair chunk of “given” inefficiency when you think about it. My guess is that our precious air-cooled engines average out towards the high side of those percentages, and more often than you’d think, exceed them. Yet, we never worry about that too much until there’s a problem relating to oil consumption or, worse, a prematurely thrashed top end. Sure, some performance addicts try their damnedest to minimize these parasitic losses (some more effectively than others), but the fact of the losses remains, as does the lack of understanding of the whole phenomenon. Not that some really smart people haven’t applied themselves to the issues over the last century or so, within the industry and without, but most of the tangible results we benefit from today have really been the result of sheer trial and error over time. Works pretty well, too, which says a lot about doing it rather than talking about it. But all that is rapidly changing in the 21st century, as efficiencies, refinements and even total revisions of the internal combustion engine (as we know it) have come into seriously sharp focus lately… for the car guys at least.

In case you missed the memo, a whole new program for the reduced fuel consumption of automobiles sold in America, known by most as CAFE (Corporate Average Fuel Economy), kicks off this year, to be complied with (or else) by the year 2016. Some manufacturers like beleaguered (but more profitable than ever) Toyota don’t have much to worry about, as their CAFE only needs improving by a little over 5 percent. Others need to get with the program ASAP (and several manufacturers are in this spot) because their fleet’s fuel economy needs to go up by over 30 percent! Not that this has any immediate connection with Harleys (with no CAFE to worry about), mind you, but the areas where most of these improvements are likely to come from are directly and critically germane to our discussion. Cutting even a few percentage points from this most inefficient aspect of internal combustion is the key to getting to CAFE compliance in six years, and you can bet your sweet derriere there will be no expense spared and no stone (or hone) unturned in the attempt to really figure out what goes on with all this slippin’ and slidin’ in the cylinder… as scientifically as current technology allows.

Slipping and sliding, in essence, are pretty workable definitions of what’s different and confusing about pistons and rings, relative to the tasks performed by the other hardware in reciprocating engines. Virtually everything else in motors rolls and rotates—but not pistons and rings! Those poor puppies have to slide up and down inside a cylinder. Contrary to the exertions of all the other components, this creates unique challenges for engineers. For instance—even such mundane practices as traditional boring and honing become very complicated and sophisticated as cylinder finishes become more refined and oils become more slippery. But we’ll get back to that. For now, let’s start with the fact that, as far as H-D engines are concerned, the complex demands of pistons have been pretty well met by Mahle, the manufacturer of OEM slugs for hogs. They are cam-ground, tapered and provided with plenty of silicon for hot-strength—truly marvelous confections—and thus are one of the more trouble-free components in Harley engines since the mid-’80s. (In fact, factory pistons are one of those increasingly rare items that tend to retain the same factory part numbers from day one. Meaning, in H-D “speak,” they don’t need to be revised, re-engineered or redone. They just flat-out work—even flat out!) Though pistons are really the least of your worries, there’s plenty more to be said about ’em, both OEM and aftermarket, but let’s leave that for another day and focus on the little things—perhaps even microscopic things—that are far more mysterious and troubling.

Rings are without doubt the hardest working parts in the motor.

Goin’ in, rings have several critical functions to perform, some of which you might not have really thought about.

- They form a seal between the piston and the cylinder walls, preventing combustion gases from getting out of the combustion chamber and into the crankcase.

- They also keep oil from getting into the combustion chamber and being burned (you’d better hope!).

- Although few appreciate it, rings are what really control piston temperature (piston oilers notwithstanding) by providing a path to suck heat out of the combustion chamber and onto the cylinder walls. (Less important with piston oilers, Twinkie fans, but still…)

- They must do all this under a widely varying range of temperatures (up to 600 degrees Fahrenheit) on a less-than-ideal surface (more about that later, too), while moving at a rate of speed we can scarcely comprehend and while changing directions almost instantaneously at anything from 800–8,000 times a minute!

- They must do it not by comparatively frictionless rolling but by sliding hydro-dynamically on what is a microscopically thin layer of oil.

- Piston rings also move efficiently in all three dimensions at virtually any instant, yet they simultaneously flex, twist and “wave” uncontrollably in multiple dimensions— constantly. (And this is when they are working “properly.”)

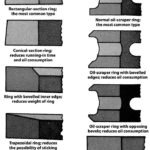

Speaking of the rings themselves; you can see there are—ahem!—“variations” galore. ’Spose you can guess which types are favored by the factory—much less the high-performance aftermarket? Can you guess why? Well, as we’ll find out soon enough, these choices make big differences in every aspect of ring function from friction to sealing to oil control—the delicate balance of which affects reliability, durability and engine performance!

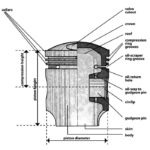

Looks pretty straightforward but the closer you look the more sophisticated modern pistons appear. For our purpose, the details pertaining to the areas where the rings live and work are the areas to scrutinize most closely. You might notice, for instance, the collar between the scraper ring and the oil control ring has a slightly smaller diameter than the one between the top compression ring and the scraper. Often as not, this has to do with different expansion rates and proper ring retention… but even such things as Rockwell hardness and surface finish of the lands can be critical, as part of the sealing “system” in conjunction with the rings themselves.

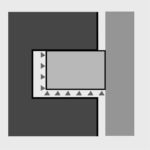

This “section” view of a ring at work is a snapshot showing that spring pressure from the ring itself seals it against the cylinder wall, while piston movement seals the ring against the top of its groove (land) on the downward stroke. You can bet—for better or worse—there’s oil in there, too!

Have you ever noted (and wondered about) the fact that cylinder wear is always most pronounced and visible to the eye at the top of the barrel? (Not that you won’t see some striations and scuffing in the middle and more towards the bottom of a cylinder, but that, more often than not, is damage or defect, not ordinary wear.) Fact is, either way, the culprit is lack of lubrication. When rings change direction at the top or bottom of the stroke, for a nanosecond or so they actually flap around like a flag in a hurricane—enough to let oil get under and behind the rings. Not good, as this means there’s not enough oil to keep the rings from touching the cylinder wall metal-to-metal. In other words, things are sliding on each other rather than lubricant! Doesn’t matter how good you think your oil is or how often you change it, folks—this is the way it is. Think that’s bad news? There’s more: It’s designed to behave that way!

Harley-Davidson piston rings (made by Hastings) are of a very sophisticated design, one element of which is a slight taper on the top of the top (so-called “compression”) ring. Some of us are aware that rings weren’t always made this way, but suffice it to say, the idea of the top taper (or half-keystone) is using it to catch the pressure of the combustion gases in order to slam the ring firmly into the cylinder wall on the way down. However, a moment’s thought tells you why this would allow oil into places where it doesn’t help lubricate. What’s harder to picture is that the amount of oil available to counteract this unfortunate tendency is greater when you are on the throttle! The over-simplified vision of why this should be is to picture what happens at the oil pump. On the gas, the pump is pumping like mad. Once you shut off the throttle, you shut off the pump as well, so backing off aggravates the situation. It’s one reason why most seizures happen not while you’re whippin’ it, but when you ease off. Hot parts (particularly rings, pistons and cylinders) don’t like running dry! Now that you have that in your head, sorry to say, it’s just an analogy. The truth is it happens at a precise point of contact in a precise place in the ring travel for a different set of reasons, more to do with physics and hydraulics than oil pumps and throttles. But it amounts to the same issue and there’s nothing much to be done for it. Or is there?

On the rest of the way around, the story changes a bit, as does the rings’ job. Fact is, all the “whoop” about compression rings needs to be couched in the realization that sealing against compression only happens during less than 25 percent of one of the two up and down trips the rings make in the course of business. Four-strokes are like that—kinda lazy when you get down to it. So, what do the rings do the rest of the time? It pretty much boils down to oil control. And like Mr. Shakespeare said: “Therein lies the rub”—literally!

To a large degree, this oil control, as you might imagine from its name, is the primary responsibility of the “oil control” ring, which these days is really a series of three (or more) thin, interconnected, specially-designed rings that sorta smear oil flung from the crankcases up and down the insides of the barrel as they move with the piston. Regardless of whether it’s old-school single-piece design or modern three-piece versions, there are “access slots” in the peripheral direction (towards the cylinder wall) providing a way for any excess oil to leave the ring pack area. The oil scraped off the walls is collected in the oil control ring grooves and transported through the piston (via holes in the oil ring land) back to the crankcase. At least that’s the general idea. Mind you, oil gets everywhere in there! For instance, some oil may run through possible gaps between the liner wall and the piston skirt. If there’s much of that kinda behavior going on, the oil is forced in front of the oil control ring—not good! Some oil control rings may therefore have a wavy spring inserted, behind the “normal” rings, if the “pre-tension” of the normal set-up is not sufficient to prevent this problem under all situations and conditions. The problem with that, if it’s necessary, is that additional force on the oil control rings causes them to have the most extreme variations in lubrication conditions, even though these are the rings that supposedly “control” the oil film! As you can see, “sealing” isn’t really the only job the ring-pack has to do. All the same, in a sense, none of this complex and radically dynamic behavior would amount to anything without effective sealing—at the right time, place and speed.

With this in mind, it’s fair to say that the “middle child,” the so-called “scraper” ring, is the most misunderstood one of the bunch. Think of it as a combination of back-up compression ring as well as the “squeegee” that steps in behind the oil ring to “bat cleanup” on that last little bit of lubricant the oil ring might have missed. All in all, it’s a remarkably effective threesome, though with all three rings doing their respective thing simultaneously there’s bound to be some overkill, even some outright lack of efficiency as a net result. I mean, state of the art or not, there are obviously still ongoing issues with things like “blow-by” (oil getting past the rings), oil consumption, insufficient cylinder lubrication and more. Why should these things still be problematic after 110-plus years of empirical improvements and insights into this whole ball of wax?

Well, we’ll have a “barrel” of fun “hatching” some new plots to address these very things—next time!