It took a while to get official answers to some of our questions about the new Indian FTR 1200. We have plenty more we want to know about this landmark American motorcycle… and we’ll definitely get to that as time passes. For the record, the illustrations here are actually of the 1200 Scout courtesy of Polaris parts online… but the basics are close enough to the FTR for our current purpose.

To keep it straight, the Q&A is unedited and plain to see, but the stuff layered on and stuck in by yours truly, TPress’s tech editor, is in italics. In addition, we’re gonna address some of the known (and possibly unknown) competition this motorcycle has and deserves… next month. Make sense?

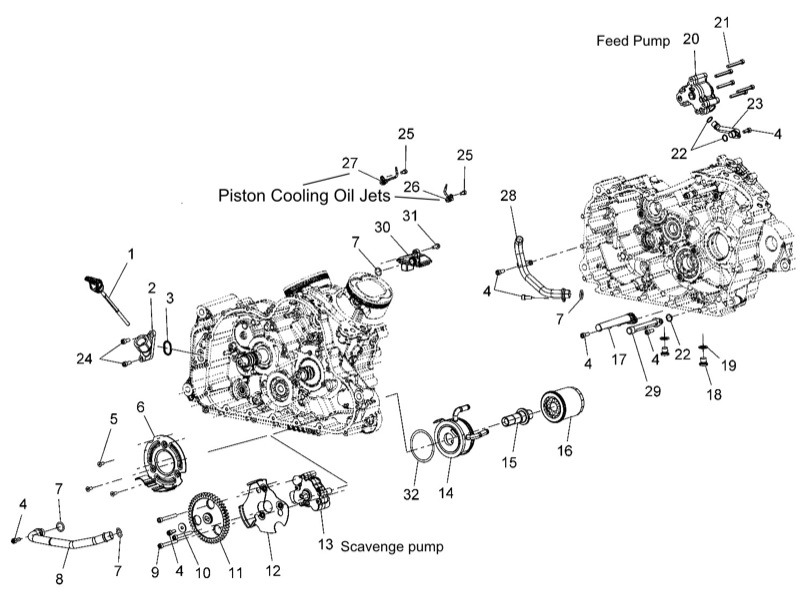

TPress: Does the FTR water cooling system negate the need for oil squirters under the pistons?

Indian: No; there are piston cooling jets for both cylinders.

Welcome to modern engineering thought regarding fluids (water and oil) as dual coolant media. Keeping rings and piston crowns within a stable range of operating temperatures is the key to reliability for high-output high-compression engines. Surrounding those critical items with rapidly circulating “media” that carries heat away is only proper and to be expected. That the FTR has it designed in rather than added on bodes well.

TPress: Is the oiling system a single or dual pump arrangement and why?

Indian: The oiling system has a primary oil pump along with a secondary scavenge pump. This helps with oil starvation due to the semi-dry sump arrangement of the engine.

“Semi-dry sump”… meaning oil is carried in it’s own small tank, cast into the crankcase but separate from the crankshaft compartment. “Helps” is an understatement… since this practically guarantees the FTR will be a huge favorite amongst those who like to carry wheelies. That which should be lubricated will be lubricated… pretty much no matter what.

TPress: How is engine crankcase breathing handled on this new engine?

Indian: The crankcase breathes through the front and rear valve covers.

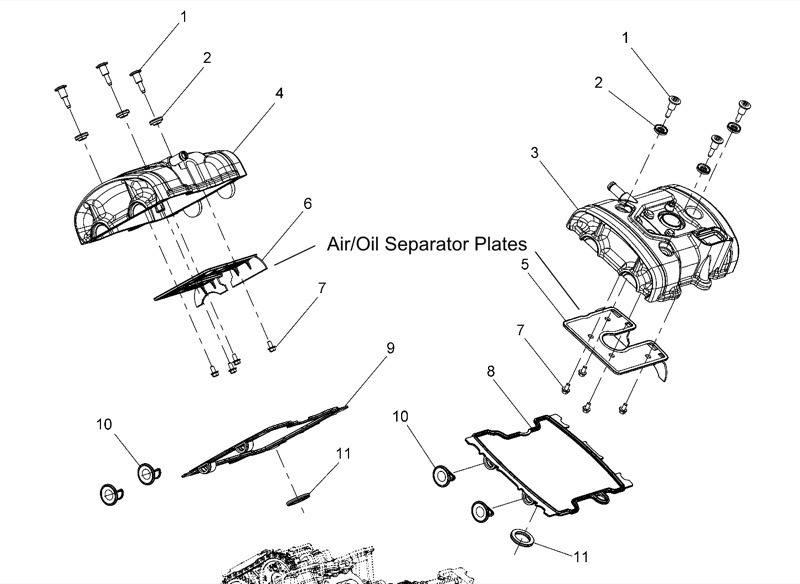

FTR valve covers are a magnesium “hat” on a well-thought-out plate-type air/oil separator (see figure 3) that almost looks like a windage tray in miniature and in reverse. Venting air out through nipples in the box top and returning oil under the plate… effective and clever.

TPress: Are valve adjustment shims under/over bucket, different thickness buckets, screw and nut, eccentrics… or… ?

Indian: Valve adjustments are made using graded buckets.

Just like the Scout… and a whole bunch of other engines designed for sustained peak power… eliminating the shims as a separate component. Not quite the maintenance-free setup hydraulic lifters and pushrods provide, but adjustment intervals are so infrequent as to be a non-issue… and you can bet valve control is superior at elevated engine speed!

TPress: Are the cylinders Nikasil with no overbore, iron liners with piston oversizes available, or… ?

Indian: Cylinders are Nikasil-lined to reduce weight and help with piston cooling. Currently there are no plans for oversize pistons.

OK… the bad news is no chance of an over-bore, should the need arise. The good news is the need probably won’t. The top end is likely good for 80,000–100,000 miles with proper attention to clean lubricant and good air filtration.

TPress: Aside from engine covers, is magnesium used in any other areas of the powerplant… and why?

Indian: Weight reduction was a large goal of this engine, however the only use of magnesium is in the valve covers.

Hmmm… not what I heard initially. But here it is from Indian’s lips. The question not asked (or answered) is why use magnesium at all… if not for all engine covers? What’s the weight saving otherwise… two pounds?

TPress: The crankcases are shorter (possibly angled differently in the chassis) than the Scout engine… but how much shorter, what angle… and why… (shorter wheelbase alone, weight distribution, both)?

Indian: The crankcase is not shorter than the Scout engine, however the swingarm pivot is located in the crankcase helping to reduce wheelbase and achieve desired vehicle performance targets.

Here again, not what I heard but it stands to reason, since the FTR is fundamentally a Scout on steroids. As for the swingarm pivot… stiff as hell laterally… and looking at the arm bodes well for stiffness in torsion as well. Adds up to quick, steady trips through canyons and on race tracks.

TPress: Does owner maintenance and service require special tools (i.e., spark plug wrench, oil filter wrench, and the like) or are standard hand tools all that is required?

Indian: There are some special tools to disassemble and reassemble the engine however these are minimal.

I was shooting for info on basic tasks, changing oil and spark plugs, and whether it would take anything you didn’t already have in your toolbox to do them. That said, this is such a modern design there won’t be much of it needed… either way. What’s good to know is that you can go beyond basic maintenance and still not need much to get the job done.

TPress: Are there any special service requirements or techniques necessary for the FTR that are different from the Scout (or other Indian) models?

Indian: No. The FTR engine is very similar to the Scout to service.

Well… there ya go! Get past the electronics and it seems routine servicing will not be beyond the capabilities of a willing owner.

TPress: At what mileages are expected maintenance/service intervals… minor and major?

Indian: Oil change—10,000 miles or once a year, with valve inspections every 30,000 miles.

Really? No more than that? What about chassis, cables, chains… and so on? Well, hang on… we’ll get to those kinds of things in a future article. For now, it’s plenty comforting to know that Indian has built this engine to meet 21st century demands… easy to care for and not needing much care in the first place.

TPress: Is the FTR “DIY” friendly for the owner?

Indian: Overall the FTR engine is fairly straightforward to assemble/disassemble.

Frankly, how much and how often is a DIY-er gonna need to “assemble/disassemble” this motor is almost a moot point these days. Statistically, the vast majority of motorcycle owners wisely leave that kind of “heavy lifting” to their dealer. It’s great that Indian has kept the few that still enjoy busted knuckles in mind though. The engine… BTW… is only part of the equation. The factory has offered several custom “packages” for the FTR and it appears that those can be easily installed by the owner. We’ll get to the specifics of chassis-related stuff in a future installment… and it’s fair to say it will all be well thought out.

TPress: By current standards… is this engine designed to be more easily serviceable and re-buildable, relative to others from different manufacturers and in what ways?

Indian: The FTR is on par with engines in this segment in regards to serviceability.

“Par” is a golf term… meaning about average. Maybe comparable to a Suzuki V-twin… but I’d bet it’s way easier (and cheaper) than “par” for a Ducati… for instance.

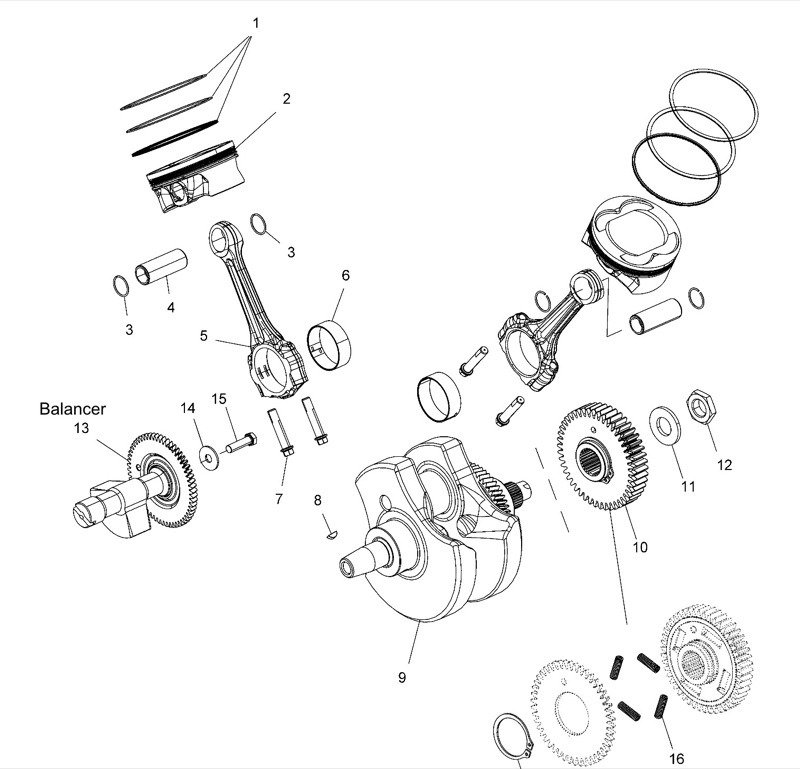

TPress: Can you describe the type of counter-balancer methodology employed?

Indian: The FTR has a single balance shaft to offset the shaking forces of the rotating assembly.

A gear-driven balance shaft… which is best. We’ll be finding out more details about “phasing” the balance for the V-angle/firing interval of the engine, where in the rev range is supposed to be smoothest by design… stuff like that, and get ’em back to you.

TPress: What element/aspect of the FTR powertrain is the most important to communicate to owners? What are its day-in day-out strengths?

Indian: Overall drivability. Some bikes are really fast, but not particularly fun to ride on a daily basis. This bike is fun around town, but if you want to take it out to the twisties and push it, it can do that too. On top of that, the engine has a lot of character and a great exhaust note due to its V-twin configuration.

That… is the best (and most accurate) answer yet! Couldn’t say it any better myself. What Indian has done with the FTR is special, very American, and hasn’t happened in too long. It’s a thrilling motorcycle that really couldn’t be made or even dreamed of anywhere else. Kudos!

TPress: Is the FTR amenable to further engine performance improvements and enhancements… and what is it’s potential in that regard?

Indian: The engine is optimized for its current configuration. As an OEM we’re limited in what we can do based on emissions, durability, etc. I’m sure we’ll see some performance mods in the future from the aftermarket, but it’s a not an area we plan to focus on.

Whoopsie! Not sure that’s a good thing to admit (or even hope for) but I admire the candor. When I read this, I had flashbacks of Harley in the ‘80s. They wouldn’t have made it without the aftermarket… then tried to crush it. Indian is in a different position, and their current stance on the matter is smart on their part. Why? Because the FTR engine is already in a optimal state of tune!

For instance, now all you can do to “hop up” your FTR is add an exquisite, expensive Akrapovic muffler, which may or may not make much difference… except for sound. A clue; there’s been no conversation about downloads or re-mapping if you do run the muffler.

On the other hand, S&S already has a less expensive upswept system, remarkably similar to the pipes with which the FTR750 and the Dirt Track custom seduced us in the first place! A clue: upswept systems, eliminate the collector “box” on the stock exhaust… which almost guarantees the need to fuss with fuel injection. Not optimal.

All the same, I sincerely hope Indian will eventually delve into factory performance parts (a la H-D’s “Screamin’ Eagle”) in the near future.