FTR750

The original Indian Motocycle Manufacturing Company was built by racers for racing (that isn’t a typo—it was originally spelled moto, not motor).

Two bicycle racers, George Hendee and Oscar Hedstrom, joined forces in 1901 to put a small single-cylinder motor in a bicycle, creating a support vehicle for their bicycle racing program. The following year they began building street bikes and selling models to the public; they also entered their first official motorcycle race—an endurance run from Boston to New York City—with one of those machines.

They won that first race.

And for the next half century Indian was a major presence on roads and a top contender at race tracks all across America. Post-war turmoil in the industry ended Indian’s run in 1953 despite a couple failed attempts to save the company by joining forces with British manufacturers. But interest in the Moto company never died and efforts to bring new life to it in the U.S gained momentum during the frenzied cruiser-crazy days of the mid-‘90s. Once court battles with the Brits over rights to the name were settled and a few underfunded attempts at forming new companies came and went, Polaris acquired the marquee in 2011. With deep pockets and a vibrant manufacturing capability it quickly reestablished the new Indian Motorcycle brand (now with an “r”) on America’s roads, and in 2017 brought the whole thing full circle and went racing again, joining the revitalized American Flat Track series.Just as the original Indian Motocycle company did in their first race back in 1902, the new Indian Motorcycle Company won its first race last season in the AFT Twins class at the premier Daytona TT before going on to absolutely dominate the entire series with a 1, 2, 3 sweep of the championship. If this season’s opener at Daytona last March is any indication, that momentum is still running fast and strong. Current champion Jared Mees took the top step of the podium just as he did last year.

It’s almost unprecedented for a first-year race team—in any form of motorsports—to attain the quick level of success Indian has. Twice, in two separate interviews, Gary Grey, now Indian’s vice president for Racing, Service and Technology, told me in a kind of “pinch me I can’t believe I’m not dreaming” statement that Indian himself was just as surprised as any race fan with that level of performance by summing up the season with a simple understatement: “It was pretty amazing.”

So, how did Indian manage to build such a wonder machine and get three of the best riders in the business to compete on them? Probably—counterintuitively—it was the new company’s lack of experience with racing that gave them a head start when designing a new racing motorcycle. They didn’t have an old model to upgrade, they didn’t have a street model to try to convert into a racer, and they didn’t have anything to do but set a goal and work towards it.

What they did have was a clean sheet of paper to design what they thought would be the best racing motorcycle they could imagine. They had deep resources and access to world-class engineering. And, along with taking on the obligations that come with resurrecting one of America’s darlings, they had inherited a rich and storied racing heritage. They had a dream.

We all know the heart of any motorcycle is its engine, and for the FTR750’s engine development Indian turned to Polaris subsidiary SwissAuto, which has a long history of building high-performance racing motors. It’s actually not difficult to build amazingly powerful engines today. The technology exists; some production sportbikes are capable of 200-plus horsepower in a 1000cc power plant. The hard part is making all that power usable—“getting the power to the ground,” as they say. Too much power, or unpredictable power, and the rider will be spinning up the rear, throwing dirt into the air behind the bike and watching himself drop in the running order, or sliding the rear out in corners and crashing.

The FTR750 (750cc is the series spec) produces a bit more than 100 hp, but it can be tamed with an external flywheel that can be easily changed—lighter or heavier—according to track conditions. The engine is kept compact with a narrow 53-degree V-angle so it can be adjusted in the frame to alter weight bias as needed. Engine internals, the crank, rods and valves are all steel to keep costs down. Its designed service life is 30 hours before a total rebuild, so that’s a complete refresh every couple race weekends, a workable compromise between high-tech and temperamental, and slightly lower or heavier but stone-cold dependable. Of course it’s fuel injected and fitted with a programmable engine management system. Computer techs are as essential to a successful racing program today as the mechanics and riders. It runs a four-speed gearbox with a relatively simple clutch, as there isn’t much shifting in a flat track race.

The black art of motorcycle racing lies in chassis setup; it’s a balancing act of compromises. Every gain in one area decreases something in another: when a bike is set up for maximum stability for fast runs down a long straight it loses ability to turn sharply and quickly. Set up for optimum turning geometry it may get twitchy between turns and affect rider confidence or be hard to handle when off the perfect line trying to make a pass.

To make all these adjustments possible the wheelbase can be lengthened or shortened, fork angle can be tightened or eased, the swingarm can be moved in relation to the drive sprocket. One position will allow it to squat and dig in when the dirt is hard and packed, another will keep it lighter for soft or wet conditions. And aligning it as close to the sprocket as possible will keep the chain from loosening and possibly flying off when landing a jump on the TT tracks.

Gary Grey mentioned that Indian began using different-weight rear wheels last year to help manage power delivery, a tactic other teams have adopted for this season also. And of course proper damping and rebound in the shocks and forks is essential. Also, a certain amount of flex should be designed into the frame. Conventional wisdom used to be that the stiffer the frame the better, but experience showed as frames got more rigid riders began having issues in turns. Frame flex works for a bike that’s leaned into, or sliding through, a turn just like shocks do when it’s upright. Another bit of engineering alchemy for designers to work into the mix.

That’s the hardware.

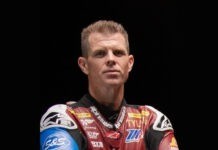

The other variable is the human element—the riders. Obviously Indian would have been keeping development as quiet as possible, but what was known was interesting: Top riders began contacting Indian asking to be on the team, even before learning final details about the bike itself. Gary Grey said, “We put together a list of 10 riders we’d like and Jared [Mees], Brad [Baker] and Bryan [Smith] were all at the top, but we didn’t think we had a chance.” All these guys had factory rides or past championships and coming to a new team, riding an unproven bike, is a huge risk carrier wise. But their faith in the project has certainly paid off.

It’s like the gods of speed are smiling down upon the new race team—and so are fans.