It had to happen sooner or later!

Harley Twin Cam engines, as produced so far, are really smaller versions of a 120-inch power plant originally envisioned back in the late ’90s. They’re not unlike the situation with Evo Sportsters, which can “grow” from 883cc to 1200cc with mere parts swapping, and totally different from the Evo Big Twin which was never anything but 1340cc during its production life. Up until now, the arena of big-inch high performance motors has been pretty much left to the aftermarket. Even in Harley’s own Screamin’ Eagle Pro catalog, the giant so-called crate engines for so-called race applications were from JIMS, not The Motor Company! Meanwhile, the factory, in time-honored fashion, has been doling out displacement increases… incrementally. First we got the 88″ engine (and a 95″ big-bore kit), then a 96″ version (with 103″ capability), then some models (notably Police units and the Tri-Glide) got the 103″ as standard, with more of that to follow in 2011, and finally 110″ CVO bikes and “kits”—all for “street-legal” applications. Of course, there were performance upgrades (of the decidedly “off- road” type) along the way, but the only serious option offered by H-D was the 113″ kit. No engine assemblies!

Let’s do a quick reality check on this state of affairs. The 88″ engine, as delivered, was good for about 60–65 hp. A legal 95″ boost got you near 70–75. The 96″ motor really didn’t pony up on the 88″, as much as it made more torque, but let’s be kind and say 65–70 hp wasn’t out of the question, off the showroom floor. Turning that into a 103″ or even 110″ engine (with warranty), typically netted some 80–85 hp, not to mention the torque boost. All well and good, but for those who sought a more serious outcome for their investment, aftermarket engines offering over 100 hp were still the only way to—well—go!

It’s certain The Motor Company noticed. The result, the Screamin’ Eagle answer to the aftermarket challenge has appeared in the pages of my favorite publication (except this one, of course): The 2011 version of the Screamin’ Eagle Pro catalog. Folks—it’s a beaut… and a brute… and great value for the loot!

There are clear reasons why this is a big deal—and some not-so-clear ones. One of the clearest is the factory’s decision to release the full 120 inches we’ve been waiting for as a race motor. This allows them to torture-test all the revisions and updates in a decade of Twin Cam design, in a package that has no warranty. They know the bulk of potential buyers will shy away from it. Thus, a manageable field population of these engines will eventually give them the feedback they’ll need to put tamer, emissions-legal and warranted versions into production bikes in the future. Logical and even shrewd, yet for my money, there’s no reason to let a warranty stand between you and the enjoyment of an engine they themselves refer to as reliable.

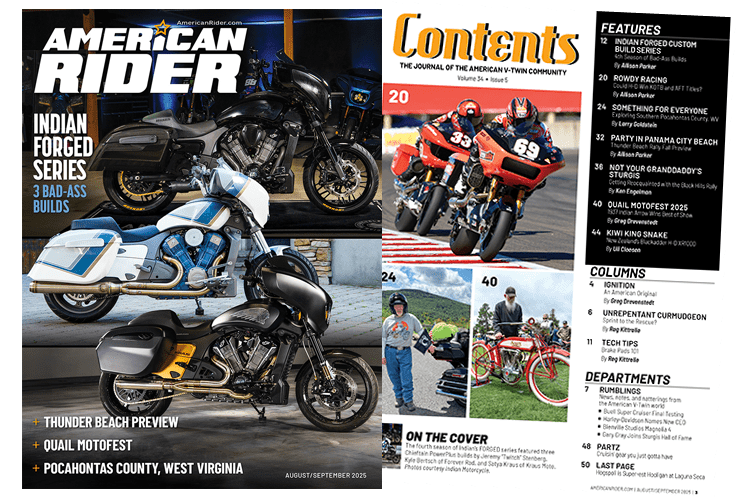

This nifty cutaway of the state-of-the-art SE120R is entertaining but not all that revealing when it comes to the intricacies of Harley’s first true high-performance engine assembly. The Motor Company has (finally) pulled out all the stops and offered the few hundred who can appreciate it—a real rip-snortin’ Twinkie!

Since the bald specifications are there for anyone to see, my task is to help you see a little further than what is on the page. The trick is to know where to begin. Maybe that should be with a run-down of the parts—most of which are available in an equally new kit (#92500001)—but not all! On the other hand, naturally, there’s the expense, so let’s run it down that way, too.

Let’s say, for the sake of conversation, you bought this kit (sticking to round numbers) for $4,700. This would get you most everything you’d need for a good start on converting your existing engine—heads, barrels, cams, crank and sundries. However, there are some pretty major bits that I believe would be absolutely necessary to get good results, which aren’t included in the kit—but are in the crate engine assembly. Notably, automatic compression releases, the beefy compensator and the proper crankcases! These critical extras sell separately for $35, $300 and $600—respectively. So, here’s the first thing that doesn’t add up (so to speak)—for me. To acquire all the individual bits and pieces deemed necessary for this 120-incher, as a kit, would amount to $5,600– $5,700! Yet—the assembled (by hand) crate engine retails (according to application) for between $5,500 and $5,800? This “investment” even compares favorably to the $4,000– $4,400 you’d have spend on a regular replacement 96” engine assembly, let alone the $5,200 and up a “legal” 103″ costs! I can’t tell you how many times I’ve seen folks spend more to hop up their stock engine than it would cost to replace it with a version designed to develop more muscle than they’ll ever see out of a breathed-on production engine. In other words, if serious power is what you crave, this new Screamin’ Eagle 120 crate motor is quite simply the most cost-effective way to get it… period!

There are more pieces that have sprung forth to complete and complement the SE120R engine. First up; the brand new 62mm throttle body (#27300019) you’re likely to attach to it, selling for $450, not including the recommended high-flow injectors (#27797-07) for $140 and the matching manifold (#27082-10) adding another $340 to the induction tally. (One caveat to fly-by-wire Touring bike owners: the nifty throttle body only works with throttle cables, so you’re gonna have to opt for the FBW 58mm version.) After that, you’ll need a serious clutch, something like the one you get from H-D such as a hub kit (#37976-08) and plates (#37980-10) for the sum of $340, or if you have a five-speed (#37970-03A) for nearer $380. The final touches, as Harley so vaguely phrases it, would be to “add your choice of race exhaust, high-flow air cleaner and tuning.” Not quite as straightforward and simple as it sounds but still, at the point before these choices must be made, you’d be looking at $7,000, plus or minus. Certainly, in absolute terms, not cheap… but in its way a comparative bargain nonetheless; mostly because of what you get for your money, and what you could get for yet more money once you have the engine.

The SE120R engine is as potent as any other of its ilk, as delivered. But for those to whom too much is never enough, there remain—believe it or not—more parts to hop it up even further! How about 12:1 pistons, for example? Or perhaps new RX-267 cams, with 660 lift and timing numbers that tell you it ain’t for fartin’ around? In short, this new factory powerplant, as delivered, is one of the brightest spots on an otherwise bland performance horizon. Since the parts are already available to take it to even higher levels of output, it strikes me as a somewhat late but incredibly great “end run” by the factory into the hot rod crate engine arena. It also speaks eloquently to the philosophy of waiting until the competition have pretty much shown their hands before laying down The Motor Company’s cards. The SE120R is the nuts!

Who else, for instance, offers stainless steel piston rings with patented titanium working surfaces? What makes them so superior and unique is enhanced wear resistance. Titanium, like hard chrome and a couple of other tough metal coatings, has been tried before on rings, but flaking and striation were pesky, problematical issues that kept any of them from becoming mainstream technology—until now. A brilliant tribologist, Wolfgang Issler by name, worked out a bonding method for Mahle (long-time German piston maker and supplier of OEM goods to H-D) that ensures the titanium stays put and delivers both anti-abrasion and anti-corrosion protection to racing engines. It’s practically indestructible and a bitchin’ leap forward for anyone intending to hammer a race motor.

Another interesting note; the friggin’ huge intake valves used in the heads of the SE120R (and in the virtually identical SE “Hurricane” heads introduced last year), which seem out of proportion, relative to the exhausts. To a head flow fan, these valves appear to be too big for good velocity at much less than WFO engine speeds. Sacrificing velocity for volume isn’t an unheard-of error in head flow experiments. The factory has avoided this pitfall by careful shaping of the ports themselves, with so-called “D” floors… and the calculated specs of the camshafts offered for this engine. Coupled with ample displacement, it boils down to having the best of both worlds.

The list goes on; the beefed-up compensator will cope with drive loads seven times stronger than stock, the crankcases are stouter and use a heavy-duty, so-called “Lefty” bearing and so forth. All this and more bespeak an engine that has been up-rated and engineered in every way to effortlessly do the job most of us always wished for. The SE120R may be marketed as a race engine, but make no mistake—it is nowhere near the radical, unreliable rattletraps we often associate with that term. Rather, it is an over-built alternative to tame production engines, with more torque at idle than most stockers make at peak, and rated at 135 hp at the rear wheel (but showing even more than that on the dyno chart)!

If power is what you crave you could do a lot worse, and probably no better. Kudos, Harley—we always knew you had it in you!