Where were we? Oh, yeah… in search of improved stopping, right? In that regard, we aren’t exactly the first to try. From the days of no front brake at all to the bristling squad of rotors and calipers festooned all over both wheels today, it’s always been about hauling the beast down in the best fashion possible. Tricky that! Motorcycles are actually the trickiest of vehicles to stop because of the dynamics involved in the function of two-wheelers. From abrupt weight transfer to the fact that the damn things lean over to turn… the nuanced interplay of balance, traction, loading and more means the motorcycle borders on unpredictable in its drawbacks and its capabilities when decelerating.

When motorcycles were young, traffic was practically nonexistent and roads were dirt; the lack of a front brake was based in large part on the notion that steering and braking should not be done by the same wheel at the same time. A rider needed to concentrate his skills and attention on keeping the machine upright in a muddy rut that might be halfway to the hubs. The rest of the bike would follow along just fine when the “anchor” was thrown out at the rear… a sort of “yank it straight” philosophy. And why not? If it took a bit of distance to completely halt, what of it? There wasn’t much to hit except the ground.

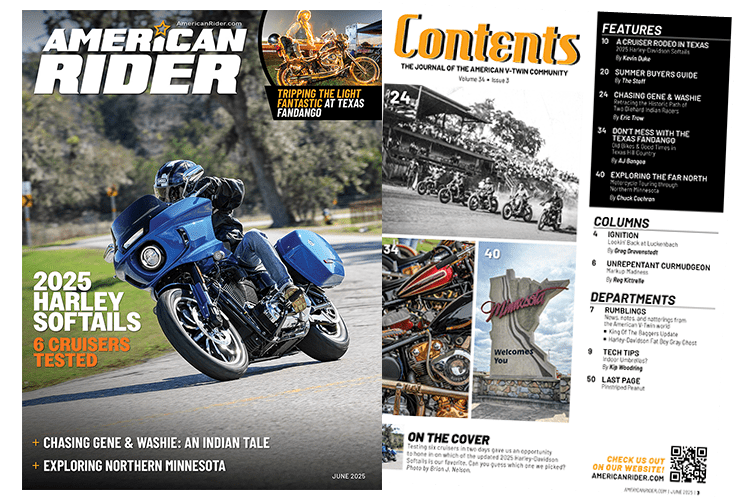

CAPTION: Light six-piston calipers with individual pads for each of the pistons—plus ultra-light LRB metal matrix rotors, times two—attached to one of the lighter versions of H-D cast wheels, suspended from full adjustable cartridge-damped forks makes for one of the best-riding, best-handling and, oh yeah, best-stopping setups for hogs. Two-finger throwdowns with all the directional control you need in anything less that an emergency. For emergencies without ABS to play backup roles, there is no substitute for practice and adequate following distances. (The former teaches you the latter, BTW.)

Once pavement caught on and Fords began to compete for, then control, the space available on the roads of the day, someone finally figured out that you could double the odds of stopping before you nailed the Model T in your face by doubling the number of brakes on the motorcycle. Tah-Dah! The front brake shows up! Not to waste a ton of time on the subject, but as “stone age” as those dinky, early brakes were, they evolved with the times better than most imagined and were the only game in town for over seven decades! The fact is, when disc brakes started showing up on motorcycles in the 70’s—on the front only at first—a good drum would out-stop the disc by an average of 10 feet from 60 mph. Magazine articles from the era confirmed it time and again! The trouble was/is; A) they could only do it once or twice. After that it was pretty much “game over” with fade, cracked and oval-ed drums and the smell of roasted asbestos putting the “exclamation point” at the end of that statement. B) Not that many drum brakes were good, and Harley’s offerings were not on the list. C) The whole notion of the best way to stop a motorcycle was in for a rethink. By that I mean more and more control of the retardation process had become the province of the front wheel. Though it took the better part of a decade to get disc brakes to work worth a damn while wet, once they did it was a revelation. It was like you didn’t even need the back brake! Well, you didn’t need it to upset your stop, but rather to stabilize the chassis, a very different thing. Technology got there quicker than human behavior, that’s for sure. Even now, there are old-timers who are convinced it’s the back brake they need to stab in a panic. The reality is quite a bit different. Look not much further than Buell and its dinky, virtually unlockable rear mini-disc to see the point… in the metal, so to speak.

All this technological progress, versus the lack of progress on the part of many a rider, leads us to the topic of “man and machine are one” interplay. To get the most out of modern brakes, you need to know how to use them and practice makes perfect. Sadly, that’s becoming a lost art, partly because under normal circumstances you only need a fraction of the brakes’ potential to get through the ride, and partly because the average rider is afraid of the brakes. (Kinda weird to be paranoid of the best friend you have on the vehicle, but there you have it.) But perhaps more than anything, modern braking systems are very much taken for granted… until (and unless) the chips are down. A good rider-training course can take care of the first two issues. Let’s see if we can address the last one.

CAPTION: Of course for those even more obsessed with reductions in unsprung weight (not a bad obsession) there’s this approach: Move the brake off the wheel altogether! Not a perfect solution perhaps, but a workable one when done as well as this. Concerns with spline wear on the tranny shaft remain, although one easy way to work around it is use the front brake alone, almost all the time. There are other issues not so simple to define, defend or defeat… but as an alternative to having a 40-pound anchor (in both senses) hanging on the rear wheel, this notion is worth trying in my book.

Since we used the last episode (er… column) talking about pads, friction, rotor materials and the like, we only need to recap some of those. Briefly, a switch to carbon/Kevlar pads is the first and best thing you can do for cost-effective brake improvement. Then, when the budget allows, swapping to metal matrix rotors would be a good move to retard movement. After that, a hard look at improving front suspension would be in order, because therein lies one of the major bugaboos of efficient, effective and consistent stops. Damping controls wheel movement. Wheels control tires and tires control stops… when they are in contact with the ground.

So few people grasp this simple truth, and its critical implications, that even the notion of switching from the “one size fits all” type-E Harley fork oil to slightly more viscous Screamin’ Eagle fork oil escapes scrutiny. Yet the SE fork oil exists for a reason and 900-pound baggers with a heavy fairing living above, or hanging on, the front forks would benefit from that reason. Changing to SE fork oil on those models slows down damping, notably compression damping, which translates into the wheel not so easily leaving the ground after a hard hit and the fairing contributing less to unintended weight transfer on washboard roads… and so on. A simple change for a minor advantage, but a legitimate improvement nonetheless. Since the term “under sprung and over damped” was practically coined by Harley riders, spring rates (and types) bear scrutiny as well. Often as not… a straight-rate spring replacement and upgraded dampers (or the addition of Race Tech Gold Valves to older models) transforms the pavement-gripping abilities of average Harley forks. More contact more of the time equals more grip, which equals better handling and shorter stops. It’s that simple. Alas, it’s also that hard. The next time you and your buddy have to “crash dive” side-by-side on the tarmac and the one with the proper mods pulls up a bike length or two quicker and the other hits the Buick… well… it’s also that important. And, just in case you’re thinking, “I’ve got ABS—I don’t need to worry,” I’ve got a word or two for you as well.

CAPTION: The new most expensive bespoke motorcycle in the world uses this (Beringer) design, essentially a four-disc front brake! Whether just to be different or because they have evidence it is indeed “superior,” the 2014 (90th Anniversary) Brough Superior SS100 certainly backs their choice with implied performance in all categories—especially stopping power! Much about this 4-disc notion intrigues. A claimed 20-percent improvement in stopping distance over conventional designs and cooler brake temperatures are certainly reasonable. The two-pound weight savings over a pair of 320mm cast iron rotors is frosting on the cake.

As good as they are, anti-lock brake systems have limitations. More of them than you might think involve exactly the same stuff we’ve been over. The system can’t work any better than the hardware allows. So better pads, rotors, etcetera, still applies! But more than that, as the name implies, ABS works by not allowing the tire to skid. Let me say that again… anti-lock brakes are anti-SKID brakes! They literally back off the binders to keep traction. This is the reason that on perfect pavement, it’s very hard to tell the difference between ABS and expert performance by an expert rider. But what about less than perfect? Dirt roads, deep sand, pea gravel and snow tells a story… in that ABS will not stop as well as a locked wheel. Why is that, you ask? Because a locked tire on a deep loose surface “plows” a pretty fair amount of said surface into a wall in front of the tire… thus halting the motorcycle very quickly. ABS has been known to take 60 percent more distance to halt under these circumstances. (Maybe that’s why dirt bikes don’t have ABS?)

But plowing ain’t skidding, sort of, which is what’s likely to happen with rain or ice on hard pavement, not soft “loam.” Pavement is where we H-D riders live and the many benefits of ABS are beyond dispute or deprecation for street riders. But, that doesn’t mean it can be taken for granted (ah, we get back to that!) any more than its limitations can be ignored. At the end of the day, the big deal with ABS is not so much that it guarantees shorter stops, because it does not. Instead, ABS leaves the rider with more directional control, if it is properly maintained. I would rather have control than not, since I’m by no means an ace with the binders. But I also believe on boning up on the back story, so here it is.

CAPTION: Dry brake performance depends on a fluid not having too much water in it. Ah, the irony of it! Minimum boiling points for these fluids are as follows:

Dry boiling point Wet boiling point*

DOT 3 205°C (401°F) 140°C (284°F)

DOT 4 230°C (446°F) 155°C (311°F)

DOT 5 260°C (500°F) 180°C (356°F)

DOT 5.1 260°C (500°F) 180°C (356°F)

*(Wet boiling point defined as 3.7 percent water by volume)

Harley (as usual) is pretty tightlipped about the specs on their proprietary brake fluids. That said, it is actually damn good stuff, testing on the high side of “spec” for both DOT4 and DOT5. Thing is, it can get quite strange when a DOT4 fluid performs in the same league as DOT5.1, yet won’t call itself 5.1? For instance, Harley DOT4 in most circles would be considered a Super DOT4, because it performs at high temperatures every bit as well as DOT5 or DOT5.1—but—some ABS systems (though not Harley’s) require a fluid that will not thicken at super-low ambient temperatures. (Mostly “Mil Spec” stuff destined for driving in Antarctica, it seems.) So, it’s this cold-weather viscosity that makes Super DOT4 and DOT5.1 different.

All the same, if you don’t happen to ride either one of the Poles often, there exists a precious few brake fluids (and one in particular) that would probably qualify as DOT6—if there were such a thing! Castrol SRF is not gonna be sitting on the shelf at the average dealer or auto parts store, but might be worth seeking out (just Google it). This stuff has wet boiling point (518°F) that’s higher than the dry “BP” of DOT5 and/or DOT5.1, and is “synthetically” manufactured to hold moisture in suspension, rather than corrosively “pool up” on critical parts. Best brake fluid on the market, bar none.

Along with ABS on Harleys comes DOT4 brake fluid. One could (and probably should) cover the facts about brake fluids in the near future, but for now suffice to say the switch from H-D’s longstanding love affair with DOT5 to what would appear a retrograde fluid was necessary—and a nuisance. DOT5 is too “compressible” and inconsistent in its behavior to be suitable for ABS systems. DOT4, on the on other hand, wrecks paint, typically has a lower boiling point (more on that in a moment) and, worst of all, absorbs moisture—a lot of it. Since we are all dedicated to complete knowledge of our vehicles, we all read our owner’s manual, right? In the manual (any and all of ’em) it says that we should change our brake fluid every two years. We then proceed to ignore that advice, usually based on experience with cars. Well, cars have metal brake lines and better-sealed hydraulic circuits than Harleys (or most any other motorcycle), which use rubber hoses and often times screwed-together connections… which conspire to ensure the ingress of water! Many another situations exists, which lets moisture get into DOT4, not least the simple act of pouring the stuff into the reservoir. It will suck water from air… being Glycol based! A pretty nasty fact of life for a fluid of choice in a system that above all else cannot tolerate moisture in order to function effectively. The pump can rot out from rust, the caliper bores can corrode and the master cylinder… well, need I go on? So (if you’ll pardon the expression) what it boils down to is, you can no longer afford to ignore the biannual fluid purge, because wet brake fluid also “loses” its boiling point! If that happens, ABS can fail and even a regular brake… won’t!