I’m not here to diss or endorse. I’m sure as hell not going to dismiss either! You may take your oil filter for granted, but this small, inexpensive part of your Harley’s lubrication system plays a vital role in protecting the engine from premature wear. (Much more vital in fact, than your choice of oil!) Each and every moving part re-quires clean oil for proper lubrication and lasting life—especially if they move against or in conjunction with another part that’s stationary (like pistons against cylinder walls, for in-stance). The oil filter is responsible for this cleanliness, as the oil passes through the filter element/media. Properly done, this prevents abrasive contaminants in the engine lubrication system from damaging engine parts as well. The trick is to figure out what properly done really amounts to.

There are two main filter “types” for Harley engines:

Cartridge filters—with a housing and a removable element, which contains the filtration media. There are a couple of underappreciated advantages in a removable filtration element, in that the “seal” in the lines between the engine and filter is not disturbed and you can see exactly what’s going on with “contaminants” in the element every time you bother to examine it. Frankly, there’s also less waste.

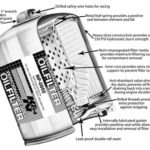

Possibly you’ve seen cutaways like this before, and each brand touts its “features,” just like this one from K&N. Yet—as with most other “brands”—these are actually made by Hi-Flo Filtro, a British-owned manufacturer in Thailand. Forty-some years old, the company uses only premium quality materials from well-known makers: Steel from Toyota Tsusho and NKK, Japan; Glue from Henkel, Germany; paper from Ahlstrom Filtration, Finland; Hollingsworth & Vose, USA; and Awa Paper, Japan. Good enough to be OE for car companies like BMW, Peugeot, Ford, Toyota, Mazda, Suzuki, and Nissan. Whether they (or any other) are best for your Harley—you need to decide.

Spin-on filters are enclosed, self-contained and attach directly to the engine via a threaded fitting. The main advantage is that used filters are easily removed and disposed of, but there are some pragmatic downsides all the same. For example, care must be taken not to overtighten the new filter when installing/accessing the damn thing in the first place and—yes!—inviolate little chrome cans do contain secrets and mysteries (as well as the grunge) we don’t see and often wouldn’t comprehend if we did.

There are also many types of “media” (the filtering material in the oil filter element) which essentially determines the efficiency, performance and useful life of the oil filter. Regard-less of the material used for media the essential parameters of oil filter elements are:

1) Filtration efficiency (not to be con fused with particle size retention)

Essentially the measure of the degree to which the filter can retain particles of various sizes. Optimum particle size retention quality in filter media is determined mostly by extensive engine-specific wear tests including exhaustive testing of filters used in racing, and sophisticated laboratory tests. Media in quality full-flow oil filters is theoretically able to trap and hold essentially all the contaminant particles larger than 25 microns, as well as a fair percentage of those quite a bit smaller. (More about that shortly.)

2) Dirt-holding capacity

The amount of contaminant that can be removed (and held) by the filter until the filter ceases to function. Capa- city that’s significantly more than the minimum requirement is obviously desirable, to efficiently filter all the oil during oil and filter change periods.

3) Resistance to oil flow

Typically achieved via the use of arch-pleated, prescription-blended media. When new, even media with a maximized number of pleats has less than 2 psi of pressure drop when filtering oil at a rate of 4 gallons per minute at normal operating temperature. It follows that minimal increase in resistance to oil flow while in service, also protects vital engine parts more effectively over the proverbial long haul. Thus putting off the proverbial overhaul!

So much for the object of the game in oil filter land. But as always, this isn’t the whole story. Some of the rest is revealed by the study of certain component parts of an oil filter. The rubber gasket provides the critical exterior seal between the filter and engine at the mounting surface. The mounting plate prevents deflection (movement) at the gasket-sealing surface. This heavy gauge steel plate incorporates the threaded hole used to attach the thing to the engine. The inner element support seals and stabilizes the inner element and the mounting plate to prevent the bypass of un- filtered oil. The upper end cap retains element end sealant and filter media, is the outlet for cleaned oil, and in-creases structural rigidity in the pleated media. The lower end cap retains element end sealant and filter media. The center tube provides internal element support. There’s a fair diversity of design here, and so-called spiral designs typically reduce initial flow restrictions when compared to some other designs. The coiled spring en-sures a constant load on the inner element to maintain the seal between the upper element end cap, the inner element support, and the mounting plate even during pressure surge situations.

The filter canister encloses the assembly with a mechanical seam—hopefully a good one—often of “double locked” construction. Some canis- ters have “flutes” at the closed end for ease of removal with an oil filter wrench and—as we all know—some don’t! The anti-drainback valve damn well better stay flexible in extreme temperatures, in order to manage consistency in oil flow (or should I say inconsistencies?) and keep oil in the filter to prevent engine-destroying dry starts. (Cheaper, older Nitrile valves can harden and become ineffective over time—not good!)

Not all full-flow filters include anti-drainback and/or filter bypass valves. These types of filters are identical to full-flow filters, except that a bypass valve replaces the inner element support and an anti-drainback valve has been added. This is done to prevent oil from draining out of the filter inlet holes when the engine is shut off. It also provides the seal between clean and dirty oil at the upper end cap. This is necessary in applications where the oil filter is mounted in a horizontal or inverted position. (But, just so you know, some older Harleys like mine don’t need an anti-drainback valve—since the open end of the filter is pointing at the sky when the filter is installed. Meaning, oil naturally drains into the filter, rather than out of the fil-ter and onto the ground, as do the side-ways mounted filters on late models.)

The filter bypass valve, as you might imagine from the name, is a spring-loaded valve that ensures continued engine lubrication by allowing the oil to bypass the filter, if the “full flow” gets “clogged,” or excessively restrictive to oil flow for any reason. It works the other way too, by allowing even immaculately clean oil to bypass the element under “high-differential pressure conditions” such as cold oil, on a cold day, during a stone-cold starting of your scooter. (Some older Sportsters actually incorporate an “oil control” valve built into the oil filter mounting as part of the engine).

Design and implementation of all these common component features and functions are interpreted liberally by manufacturers, to say the least. As much as filters may look alike at a glance, closer scrutiny reveals more differences than similarities. Some subtle—some blatant! Not all filters work alike because they are not built alike.

Now, a word from our manufacturers! Well, maybe not—since they aren’t really talking and there are only a few left in the good ol’ USA anyway. Fact is, there are some fairly reliable “telltales” that you can use to de- termine who made your filter (regardless of the name on the wrapper) if in fact, it was made here. Most filters are not! They are made overseas and that’s not bad—only confusing. Can’t tell those players without a scorecard and they aren’t showing their cards.

The telltale signs

Eyeball the business end and even more subtleties present themselves. The holes (both in size and number), the center tube, the drainback valve design and material, even the threads can ultimately affect the filter’s ability to perform its three main functions… at least for intervals that are long “enough.”

Purolator filters: eight medium-sized holes for the oil inlet and nothing but a black (or orange for the Pure One) diaphragm to be seen through them. There are six large crimps holding the gasket in place. Through the center outlet hole, you can see the spring for the bypass valve.

Champion filters: six large holes for the oil inlet, one of which is larger than the others. Only the black anti-drainback valve can be seen through the inlet holes. There are six large crimps holding the gasket in place. Through the center outlet hole, you can see the bypass valve spring. Usually, the backplate metal is dull, or even rusty.

Fram Extra Guard: eight small holes for the oil inlet and a thin, cheap looking backplate, and is currently stamped with a “2Y.” There are five very small crimps holding the gasket in place. If you look into the center hole all the way to the top of the filter, you will see a kind of “button” in the end cap of the cartridge (which looks like it’s made of metal from there). This is the plastic bypass valve.

Wix: six large holes for the oil in-let with only the black anti-drainback valve to be seen through them. There are six “notches” that hold the gasket in place. Through the center outlet hole, you can see the bypass valve spring. Usually the backplate metal is shiny.

AC Delco: five large holes for the oil inlet and six spot-welds on the rim surrounding them. There are no crimps holding the gasket in place. When you look through the inlet holes, you can see the metal bypass valve with its 12 small holes and the black anti-drainback valve diaphragm around it. Through the center outlet hole, you can see the spring for the bypass valve.

While it might be helpful to identify a filter, if ever there was an in-stance where appearances (alone) can be damn deceiving—this is it! The whole reason for giving you all these basics is to offer a few guidelines for selecting your filter. You might, as most would, presume it’s easiest and safest to simply buy the factory’s filter all the time. Just do that and save any extra effort, right? Yeah, well, first off, that’s as naive as figuring your engine is absolutely perfect and cannot be improved, smog equipment and all, as delivered from Milwaukee. Maybe so, but prob’ly no! Secondly, Harley doesn’t make Harley oil filters and over the years they have changed designs and sources, not to mention having “Superpremium5,” “Genuine” and “Eagle Iron” or (as they prefer to call them these days) “Classic” brands to offer. They are not even close to identical! The Mo-tor Company has even taken a stab at “green,” more eco-correct, filters with their new “Definitives” brand of cartridge filters. Where they tend to steer customers in the wrong direction is with all this blather about “mi-crons”—as if that were the best and only criterion upon which to base a wise selection.

Micron is just another term for micrometer (1 millionth of a meter). A micrometer is a unit of linear measure in the metric system—like the centimeter and millimeter—used to measure length, width or diameter of objects. (Its scientific notation is µ and an object that is 1 micron in size is 0.000039 inches in diameter.)

• 1 inch is 25,400 microns

• Diameter of average human hair 70 microns

• Lower limit of visibility (naked eye) 40 microns

• White blood cells 25 microns

• Talcum powder 10 microns

• Red blood cells 8 microns

• Bacteria 2 microns

• Carbon black 0.6 microns

• Tobacco smoke 0.5 microns

(Does it bother you that particles big enough to do damage and generate wear and tear are too small to see? Which leads to a whole ’nother conversation about the worst “contaminate offender” on the machine, the dirt-sucking air filter, and why those are not rated in microns, or anything else! But, we’ll save that for another time.)

If you unfolded all the media you see in the filter on the right you’d find there’s over two and half times as much as in the OE filter on the left. It’s a different type of media as well, stuffed in a housing that’s attached to the mounting plate in a different fashion, and using rolled threads rather than cut threads, a different type of anti-drainback design and so on. The sick thing is none of that is any guarantee that either is the “best” for your particular needs. All the same, it sure tells you not all oil filters are the same!

Anyway, typically, if only larger particles need to be removed, a very basic cellulose/paper media is used. As the size of contamination to be removed gets smaller and smaller, the type of media changes to a more complex cellulose, then to blended media where cellulose and man-made fibers are blended together in various configurations. For the removal of ex-tremely small contamination, media typically changes from one made primarily of cellulose to one made exclusively from various types of man-made microfibers.

The two most popular “reported” media “ratings” are a nominal micron rating and an absolute micron rating. Nominal ratings usually mean the filter’s media can capture a given percentage of particles of a stated size. For example, a filter might be said to have a nominal rating of 50 percent for particles 10 micrometers in size or larger.

An absolute micron rating can be determined by single-pass or multiple- pass testing and is usually obtained by passing a test fluid containing particles of a known size through a small, flat sheet of filter media. Any particles that pass through the media are captured and measured. An absolute rating is likewise expressed in the form of a percentage of the size of particles captured and can run as high as 98.7 percent. The trouble is, results from different test methods may not be comparable as their methodology varies greatly.

That means a filter that is marked or rated “10 micron” certainly has some capability to capture particles as small as 10 micrometers. However, just ’cause you see one marked “10 micron,” you can’t know exactly what this means unless you also have a de-scription of the test methods and standards used to determine the rating!

Therefore, micron ratings alone do not matter nearly as much as single and multiple-pass ratings. In fact, the Filter Manufacturers Council all but abandoned the micron “standard” a few years back. The “new” ISO (In-ternational Organization for Standard-ization) standard for multiple-pass testing provides a common, standardized format for filter manufacturers to rate performance.

Multiple-pass testing uses a specified contaminant, of known sizes, added regularly in measured quantities to the fluid which is pumped continuously through the filter. Samples of fluid are then taken at timed intervals from both upstream and downstream sides of the filter. The contaminant in the samples is checked for particle sizes and quantities of each size or range of sizes. From these upstream and downstream measurements, a (complicated) Beta ratio is formulated by dividing the number of particles of a particular size in the upstream flow by the number of particles of the same size in the downstream flow. This uniformity in filter testing gives you the ability to reliably and accurately compare published filter “pass ratings” among different brands—rather than relying on micron ratings—reflecting a truer indication of filter performance.