Let’s take up here, where we left off last issue. Last time, we covered the most obvious and important “features” of The Motor Company’s latest power plant. This time around, the focus is on the many not inconsiderable improvements and innovations applied to the “supporting players” which collectively make the new Milwaukee-Eight the best Harley Big Twin ever made. To get up to speed on this technical examination, click here and refresh your memory.

Having done that, let’s delve further into the inner workings of the Milwaukee-Eight.

Crankcases for the M-8 are all new, over 20 percent stronger, with a new front engine mount interface and a relocated oil filter mount being the most obvious changes. The crankshaft position sensor is now located on right side case at the bottom of the engine, a move also dictated by the addition of the new balancer. Inside the cases are new shouldered cylinder studs, spaced farther apart and reconfigured to handle the larger cylinders. The changes were made to accommodate the new gear-driven balance that lives in front of the crankshaft. The factory is quite rightfully proud of their investment in the high-tech machinery required to make these cases (not to mention the heads) right down to robotic powder-coating that (pardon the pun) “finishes” the process.

The new-for-2017 interface between engine and transmission cases uses a new metal-backed gasket with beaded surfaces to seal internal passages between oil tank and engine. Makes sense, when you consider the engine now breathes into this area.

The new crank runs a much larger, stiffer crank pin, as well as bigger connecting rod bearings for nicely increased load capacity. (Perhaps a hint of the potential inherent in this new power plant?) Crank position sensor “teeth” are machined into the right flywheel because the left flywheel has a new press-fit, constant-mesh, anti-backlash “friend’ in the form of the balancer drive gear.

Ah! the balancer! This clever device amounts to a single counterweight that passes between the flywheels, keeping things pretty compact, while doing a better, more efficient job than the older TC “B” motor’s chain-driven design. The gear on the balancer is a so-called “scissor” type which keeps any gear lash and associated noises to an absolute minimum.

Now… about this new single cam and its attendant drive system. A close look at the picture shows most of what you need to know. The cam itself is lighter, quieter and built into a single component from assembled pieces… namely the cam and its gear. But that cam also has larger base circles, and lobes to match the characteristics of the 4-valve heads. The cam is chain driven as you see, but what isn’t shown is the hydraulic tensioner, itself a new design which is maintenance free. The oil pressure relief valve is no longer situated in the cam plate either…

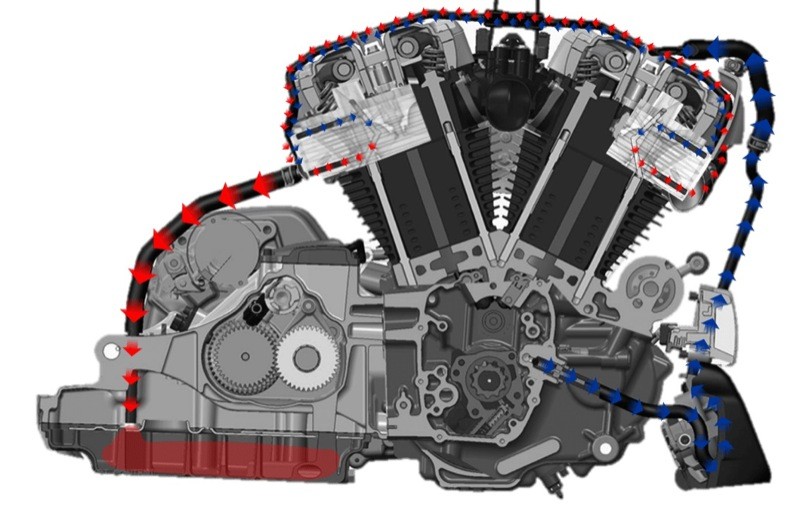

… since it has been moved to the oil pump body. The thing with the oil pump is, even though oil pressure is the same, the oil-cooled models of the M-8 get larger displacement feed rotors to ensure the flow of massive volumes of lubricant being pumped through the heads. Which is a subtle reminder that oil pumps these days not only lubricate, they cool.

Here’s how: The oil return lines deliver head cooling oil to the (bigger capacity) oil tank (under the transmission) where it passes through the separator plate (reducing agitation in the case) then gets picked up by the oil pump feed circuit, goes through the engine’s critical bits, then through the oil cooler in front of the engine cases and back to the heads to repeat the cycle.

Oil-cooled heads on Milwaukee-Eights have passages which are precision drilled in the heads to route oil between the exhaust valve seats for increased “pinpoint” cooling. Since it also moves faster, that oil also cools better.

Whereas the twin-cooled versions pump coolant to their heads via a more familiar-looking approach. Notice that this cast-in coolant passage is also wrapped closely around each of the two exhaust valves for precision temperature control and surpassing effectiveness.

Underneath the new, narrower primary cover (introduced last year on “Low” models) and used on all 2017 Touring models, is a new “assist/slip” clutch. Using either nine or 10 plates (depending on model and application) this setup uses built-in ramps which increase pressure on the plates, thereby improving grip during acceleration, yet decreasing all that to let it slip when you back off sharply and/or downshift. Eases the pain for tires and driveline… not to mention rider nerves… when negotiating treacherous roads.

The primary chain tensioner has been tweaked a bit too—mostly its “shoe” is longer to support more of the chain. But the addition of what Harley calls a “mass damper” is new. Looks a lot a like a plastic plug stuck inside the primary cover, and its task is to (you guessed it) reduce sound transmission through the cover.

Another “sound” improvement is in the compensator mechanism. As of 2017, it consists of new ramps and a special, large-diameter thrust washer, made of a unique material delivering consistent friction and superlative torsional behavior in the system. All this to harmonize with the new transmission scissor gear (first gear) for quiet, jerk-less power from crank to trans to tires.

And, in case you were wondering, this is the new scissored first gear. It lives on the countershaft, in constant mesh, and works to prevent backlash… known to most of us as neutral “rattle.” The bearing support plate (a.k.a. trap door) that holds the transmission gears also sports a new main shaft bearing. Hmmm?

To end where it all begins, there’s a new starter in town. Bigger armature, smaller solenoid, 1.6kw powerful… and exclusive to the Milwaukee-Eight. Physically compact, it cranks the new 11:1 CR Big Twin with ease and alacrity. The only downside is it is not rebuildable—though not likely to need it either. And at only $210 to replace, it can’t be too big a deal.

The increase in alternator capacity is welcomed and more than a little useful! Not least for adding all those electronic doo-dads and stereo equipment we seem to crave these days. This setup, complete with “bladed-fan” rotor design to keep things cool, will handle it all nicely. The best part is the increase in charge rate at low engine speeds, since that’s where we spend most of our riding time, particularly in town, playing stop and go. That said, it’s important to recall that the bike’s own systems (EFI, ECM, ABS, BCM, starter, ignition… on and on) suck up a large chunk of power, and in truth all that direct current comes from the battery. So, the new alternator’s main function is to keep said battery on the job.

OK, before we call it done here, you should know about a couple of important things not directly engine related. Well, maybe one is, but more likely it’s rider comfort related. Anyway, it’s a new fan kit for oil-cooled models, listed in the P&A catalog (but not shown here). Called “cool flow,” this kit, a set of mid-frame air deflectors and the new fan-assisted oil cooler—also for oil-cooled models—would be the ticket for cool comfort on hot days.

The other very important comfort-related items, which already come with the M-8 motorcycles this year, are the rear shocks and front forks. These are not to be underestimated or overlooked when it comes to a really enjoyable riding experience! The fork-damping design in particular (as shown here) with its double bending valves (as opposed to the floating ones used previously) makes a night-and-day difference on all roads under any conditions. You need to ride one of these Milwaukee-Eights… simple as that!

P.S. Forgot to mention something interesting about the rocker arms last time. Looking at this photo, you’ll notice that the arms have “water slides” leading from the pressurized oiling exit hole above the shaft, to the tip, above the valve stem. Seems as though the intention here is to rid the rocker shaft of any excess oil, cool the arms, and splash-lubricate (as well as cool) the valve stem tips and springs… all in one go. Clever!

Great article Kip,

I thought I read or heard the cylinders would be all aluminum cylinders like those great American Air Cooled cylinders you convinced me I should use on my 93 FLHTC that had a heat management problem (studs pulled out of the cases).

How are the twin spark plugs energized? Independetly or by a single system?

it all sounds great! but until the BUGS many are experiencing i will keep my already technically advanced + reliable Victory Hammer!! Polaris will prolly need a little work to meet Euro IV, competition is good for the buyer + it will be interesting what gets done to Polaris engines, especially the big injun thats taking harley sales a little @ a time. i buy what i like + feel is the best value for me, + i DO NOT drink any ones KOOL AID!!!

Hrmm. That is only something a Victory owner would say. It’s ok though… not everyone gets to actually own and ride a nice Harley. Many are happy with the various copy cat bikes- although it’s quite funny that they feel the need to post here on a Harley-specific topic.

having an 06 sportster i can attend to its reliability but the Vic although heavier handles much easier. Indians are way big for me as is their price. i see myself as a road king guy, as i tested a dyna i thought it was just a bigger sportster with the same poor brakes + suspension, but it seems HD is not taking indian lightly + stepped up with a better “mousetrap” time will tell!! the 106 solid mounted Vic is soo smooth as noted by several HD rider friends, they also echo the light feeling as well! guess i gotta test an M-8 one day.

There’s always gonna be the group of folks that will moan and groan about anything new that comes out. If companies like Harley worried about that group too much then we wouldn’t have the Harley’s we have today, even the Victories and Indians. These companies have all taken visionary steps to produce what they have. Harley has done a Fantastic job at that with also keeping the history within the current tech. Harley isn’t perfect and neither is any other company, but I’ll be on the coolest part of American history any day of the week! HARLEY DAVIDSON

That was one of the best Harley-Davidson Milwaukee-Eight 107 Engine articles I’ve rad so far, now I just have to rent or test one to see for myself.

Well victory is no more…. My buddy bought and Indian with a 111 and it sounds like a can of spray paint being shaken by a vacuum cleaner. I’m glad I got this engine on my bike. No regrets. It’s a Harley.

Why do they keep using the automatic tensioner on the primary which gets too tight and wears out bearings.

Please fix the section about the motor venting to the tranny. It don’t.

Well I can tell you that the MOTOCO gambled and lost. There are M8 problems all over the place. Mine is in for the oil light issue, p0522 and p0523 for a second time and the bike has developed at clank at startup that recedes after 30/45 secs.

I purchased a 2017 Ultra Classic in July of last year, I have really enjoyed the touring with the new M8. The only issue that I have come across recently is a clutch issue. The clutch failed to allow for changing of gears at a stop light, forcing me to start out in 3rd and dog the engine. I fixed the problem by upgrading the stock clutch to a 10 disc and replacing the secondary accuator. Wrks great.

Amen, Kal K.

I as a Harley guy, still have to admit that Victory bikes have more American made parts than Harley.