Brakes are not often given much thought, but they are a critical element for any motorcycle. They convert kinetic energy into heat through friction.

Friction is required for brakes and tires to do their thing. Too little can cause – uh –performance anxiety, while too much friction can cause excessive heat and failure in the form of brake fade and/or squirming tires. Keep in mind that tires are an important part of your bike’s braking system, so make sure they’re in good condition and properly inflated.

Whether in the form of tire traction or friction between brake pads and rotors, proper mastery of braking falls on the rider. You should practice hard stopping until you can confidently bring your tires to their friction limits. “Threshold braking” amounts to a skill that allows braking right to the limits of tire traction without wheel lockup. This is when ABS kicks in, if your bike has it.

Many of us tend towards swapping the stock calipers for something from the aftermarket to improve braking. Not a bad plan, but hardly cost-effective.

For a lot less money than fancy calipers, your bike can stop better by upgrading or enhancing the existing system. Factory brake pads typically use a semi-metallic “sintered” matrix running on stainless steel discs/rotors. Like most OEM parts, they do a reasonable job by compromising cost and performance. Good overall, but maybe not ideal for the way you ride.

A swap to aftermarket brake pads can provide improvements under some particular conditions. There are three basic types:

Organic pads: Made from mixes of fiber, rubber, Kevlar, and such, these softer-compound pads are easier on the rotors, generate less heat, and are quieter, but they also create more brake dust that can sully your wheels.

Sintered (semi) metallic pads: Made from a mix of ferrous and non-ferrous materials, this type of pad is going to last longer but is harder on the brake rotor, needs a while to warm up before they start to work at their best, and are more likely to be noisy.

Ceramic pads: Made from copper and hard ceramics, these pads work better in wet conditions but are more prone to glazing. They don’t like cold panic stops, but they work well on stainless rotors once warm.

The friction performance of pads intended for typical street temperatures is classified under SAE Standard J866, expressed as a two-letter code where the first letter designates the low-temperature (0 to 200 degrees Fahrenheit) friction performance, and the second letter denotes the high-temperature (200 to 600 degrees F) performance. The letters generally appear on the backing plate as a prefix or suffix to the part number.

If the first letter is lower in the alphabet than the second, the pad works better at high temperatures and needs to be warmed-up before maximum braking is delivered. If the second letter is lower than the first, the pad may suffer fading at high temperatures. The best street pads have good friction at both high and low temperatures. A guide to that level of consistency is when both letters match, meaning the pads perform similarly at all temperatures. HH pads are fairly typical in the front calipers, while GGs are common out back.

The letter code actually represents the coefficient of friction with a Greek letter that looks kinda like a backwards “u” with a long tail and is pronounced “mu” (moo). The idea is that a certain numeric level of “mu” can range from 0.0 (no friction at all) to 1.0 (locked-up solid, immobile due to friction).

Anyone who ever rode an old Pan, Shovel, or Sportster with a drum front brake has firsthand experience with a low “mu,” maybe 0.20, if that! Today, stock disc brakes can muster levels above 0.40. It’s relatively easy to get higher than 0.50 if we do a good job of selecting pads that work well with our rotors.

Stainless alloy brake rotors have been a feature of Harley-Davidson OEM brake systems for decades, as much for cosmetic reasons as any other. Alloyed stainless has the advantage of resisting rust and being thermally stable. Cast iron actually works better, but those rotors are heavy and prone to rust. Both of these common materials have seen some clever engineering and designs over the years in order to minimize their respective issues, but they can’t be eliminated.

In terms of the mastery of friction mentioned above, the way to look at it is in terms of outcome. A racebike makes different demands on brakes than a bagger (except for a bagger racebike, of course!). The trick is to match the pad type and rotor material for better braking with your choice of tires and typical style of riding.

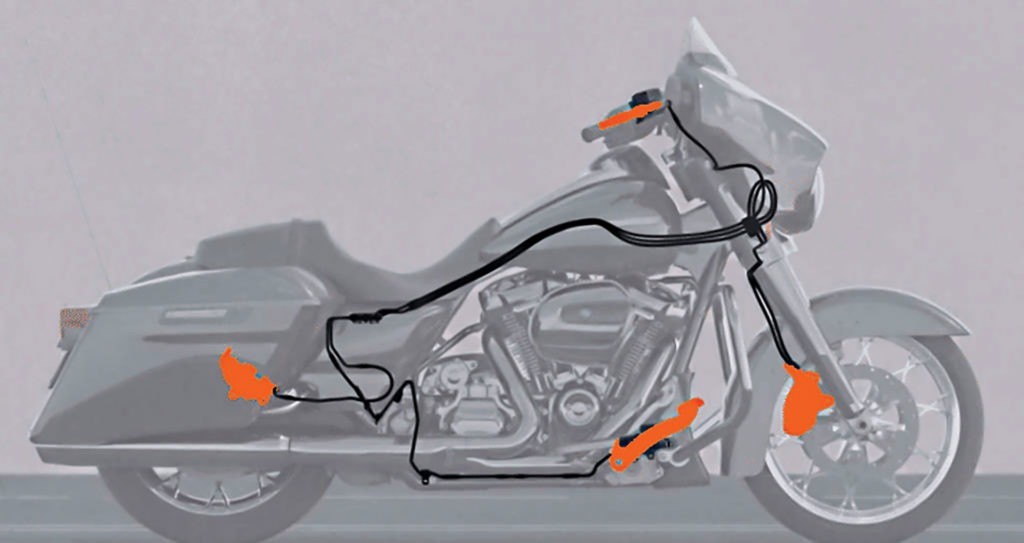

Antilock brakes (or ABS) are the biggest advance in motorcycle safety since disc brakes themselves, and they get better with each generation, such as the type fitted to the new Sportster S and Pan America.

The inclusion of bank-angle and pitch sensors help coordinate tire-slip readings at over 100 times a second in a cornering ABS system, meaning that riders don’t have a hope of out-performing the system in an emergency, regardless of their training and practice. The simple fact is that ABS –and the latest cornering ABS –can save you from a crash better than you can.

Perhaps the biggest problem with ABS lies in the rider being unwilling to grab a handful of brakes and trusting the electronics will do the rest. It is seriously counterintuitive to us old-timers, but it’s actually the best way to take advantage of ABS.

There’s also room for intelligent disagreement when it comes to stopping distance. On dry pavement under optimum conditions, it’s possible that a highly skilled rider can best the stopping distances from ABS systems.

But if presented with an unexpected emergency situation when instant maximum braking is required to avoid a collision, ABS will prevent tire lock-up so a rider can maintain control and mitigate or avoid an accident. Falling off and sliding as a result of a panic stop gone wrong is no time to debate whether ABS is helpful.

Both ABS and traction control are designed to safely enhance the tire patch/brake pad friction symbiosis. The core takeaway is embedded in the name “antilock.” If the brakes are locked, tires lose their traction and the rider loses control. Having a sophisticated electronic ally against such an eventuality is what helps modern brakes be the safest and best-performing in motorcycle history.