Nowadays, no new Harley comes with any fuel delivery device that isn’t in some way dependent on electronics. Precise fuel mixture control is vital to allow the best possible economy and lowest emissions, both for its own sake and because exhaust catalysts only work if the mixture is maintained within tight limits. A modern H-D engine uses an air-speed meter and air temperature sensor to work out how much air the engine is taking in stroke by stroke, then adjusts the amount of fuel injected into the inlet manifold by varying the time the injector is open. If you know the air speed and density (from its temperature), you know the mass flow rate. Since the fuel behind the injector is held at a constant high pressure, the amount injected depends on how long the injector is open. The engine controller calculates the time to keep the injector open based on the mass of air being consumed by referring to stored information about the “best” air/fuel ratio to use (never that far from a theoretical 15:1) for various conditions of mass flow, engine speed, throttle position, temperature and so on. There’s often also a slight tweak on the mixture based on the precise amount of oxygen left over in the exhaust measured by an O2 sensor. Plentiful, reliable electronics makes it all possible—but when you boil it down, it’s nothing more than an electric finger on the trigger of a high-tech squirt gun full of gas. Yet, there’s one other little thing!

I come to praise carburetors, not to bury them!

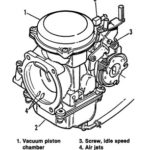

For the record, so-called fixed venturi types are what we know as Bendix, Tillotson, Linkert, Keihin (before the CV), S&S, even Weber a.k.a. “butterfly” carbs. On the other hand, the variable venturi club includes Dell’Ortos and Mikunis for certain, since they have slides—but what in holy heck do we call SU or Keihin constant velocity (CV) carbs? The Keihin in particular is a “morph” since it has both a slide and a butterfly! When it comes to jetting (really, it’s proper “tuning”), the real “Ah-ha” part comes when you study #4 (the vacuum port) and how on CV carbs in particular, the notion of controlled air “bleed” is taken to new heights and new degrees of precision. It’s saying a lot that these carbs could meet emissions standards until 2006, but perhaps it means more to say it took expensive, complicated, electronic fuel injection to meter fuel more precisely.

While the buzz is about EFI, let’s not forget that for well over a century Harleys got by nicely with a more primitive yet somehow far more elegant fuel delivery mechanism. The “field population” of Harleys that sport good (and some bad) old-fashioned carburetors, far exceeds that of their EFI-equipped brethren… with not an electron in sight! Yet, to this day, most riders know even less about the operating principles of these humble mixers than they dare to think they do about fuel injection.

A carb is a triumph of exploiting relatively simple natural phenomena to provide an engineering solution—using the technology that was available in the last century. There are some really ingenious and subtle combinations of different effects in there, each compensating the other to provide what’s required. So, just what does your engine “require” to breathe in? Well, gasoline is quite complex but mostly a basic structure of hydrocarbons—carbon/hydrogen molecules—that when burned make four C02 molecules and five water molecules, consuming 13 oxygen molecules in the process. If you stir in the weight of each type of atom, you get a weight ratio around three of oxygen to one of gasoline. But, of course, only about 20 percent of air is oxygen. The other 80 percent—mostly nitrogen—is just inert filler as far as an engine is concerned. So (and this is important), the ratio by weight—not volume—for there to be neither oxygen nor petrol left over is approximately 15 of air to one of petrol. At least that’s the ideal, a “stoichiometrically correct” mix—supposedly. In practice, sometimes you want it richer—for starting when the engine is cold and fuel condenses in the intake manifold or doesn’t mix well because of low gas speeds. You also want a slightly rich mixture at full throttle/high revs because it limits maximum temperatures and flame duration inside the cylinder and helps prevent some of the bits in there from burning out or blowing up. Best power, considered to be achieved with richer 13.2–13.5:1 air/fuel ratios, is a story for another day. But your engine can tolerate that leaner 14.7–15.2:1 mixture for cruising (which it does, thanks to the EPA) and enjoy the benefits of better fuel economy and lower emissions of the unburnt stuff.

Early internal combustion engines—the big stationary monsters—ran on coal gas, at fixed speeds and loads, so getting things right was just a matter of tweaking the gas “feed” until the thing ran smoothly—just like you do today with the idle mixture screw on your carb. The idle circuit, even today, is pretty much just that simple because the load and engine speed doesn’t vary at idle.

The first vehicle engines to run on petroleum used a simple evaporation affair that basically drew air over a bath of gas and let it suck up the vapor. Some say Bill Harley built his first one out of a soup can (tomato, as I recall). In case you’re laughing at such an arrangement, just remember that it’s pretty much the same thing as pulling on the “choke” to richen the mixture for cold starting. In that phase, your trickest, newest carb is no more sophisticated than the earliest devices. Before long though, engines had to be able to run over a much wider range of speeds. What we needed was a way to supply a correct mixture at all speeds and loads—automatically.

What we got was a Dutchman, an Italian and some Yankee ingenuity.

Then as now, the trick was to measure the amount of air that the engine was consuming, and then meter the correct amount of fuel to match. That took more figuring than you’d figure—starting back before carbs were invented.

In the 18th century, Daniel Bernoulli figured out what happens to gas flow in pipes. Bernoulli (a Dutchman, surprisingly) was able to show that pressure in a moving gas varied with gas speed, and higher gas speeds gave lower pressures. Our Italian friend Giovanni Venturi came along decades later and used these ideas more practically to devise a variable-diameter pipe (venturi tube) that exploited old man Bernoulli’s principle. The venturi tube works by forcing the gas to speed up in the constricted part and thus generate a pressure difference between the wide part and the narrow part, with the pressure being lower in the narrow part. But, like so many things in physics, it’s not what you’d think. You’d think that the constriction would cause the gas molecules to bunch up, increasing pressure rather than reducing it. Like rolling your thumb over the end of a water hose. So, what’s going on?

The easiest way to think of it is in energy terms. The gas on the way into the venturi tube has a total energy made up of two parts—velocity (kinetic) and pressure (potential). The total energy of the gas doesn’t change as it passes through. However, in the narrow part, it is going faster in order to get through. But, by going faster, its kinetic energy is higher. For the total energy to remain the same the potential energy must be less. (You can check this by connecting a pressure gauge between the inlet and throat of a venturi tube. A simple U-bend manometer will do.) In fact, let the pressure difference between the mouth (normally atmospheric pressure) and the throat (throttle bore) force petrol from a reservoir (the float chamber) through a fixed orifice (calibrated jet) into the air-stream and you have the basic mechanism of a simple carburetor. The bonus is, the liquid fuel atomises as it comes out of the orifice and mixes with all that kinetic air rushing through, becoming a gas. As the engine airflow changes, so will the pressure in the throat and therefore the pressure on the fuel, and its consequent flow rate through the jet will vary automatically. Easy, huh? Sorry—not really!

The problem is that pressure (potential) varies directly in proportion—twice the pressure, twice the energy and so on. But velocity (kinetic) varies at the square—twice the velocity, four times the energy. So, as the velocity of flow through our simple carb increases, the pressure in the throat drops too quickly (at the square of the gas speed) and the mixture would get too rich (or, if the jet size were such as to make it OK at high gas flow, it would be too lean at lower flows). This is very inconvenient, and a carb that simple just wouldn’t work. But don’t blame Bernoulli or Venturi, they just helped describe how nature works.

The big secret: “Air” un-apparent!

The trick—indeed the only reasonable solution—is to bleed air into the venturi tube’s throat in an attempt to correct this inconvenient characteristic of airflow “energy” through a tube… er… carburetor. The amount of air bled in varies with the pressure, dampening down the overall pressure drop. In a way, this is where carbs start to fall apart, since the correction is only an approximation. But it is still plenty good enough. Add a throttle to control flow (hence power), and you are in business. But even then, niggles remain.

Gasoline is about 500 times dens-er than air, so if you slam the throttle open on such a simple carb, the airflow will speed up faster than the gas can flow through the jet, causing temporary lean surges and poor acceleration, with lots of spitting back. So fixed jet carbs usually have a little pump to squirt in some extra gas to compensate for that sort of situation. Of course, mixture control goes even further to hell during other sorts of radical phases. Designs and devices to compensate for every contingency have been tried, and Lord, can it get complicated! But, if you put enough design effort in, plus have really smart compensating mechanisms, these fixed venturi carbs can be very efficient and millions of such carburetors prove it every day.

All the same, there’s another approach to accurate mixture compensation that links things more to throttle opening—the variable venturi carb! Here you vary the throat size with the throttle action. At small openings, for a given airflow the pressure drop would be higher and so such a carb would tend to lean out at high throttle openings because there’s less of a venturi. This is easy to compensate for, very accurately, using a tapered needle. The higher the throttle valve the thinner the needle in the needle jet, and so the higher the peak fuel flow. Don’t forget that for any given throttle position, the basic richening at high airflows problem still exists, so an air bleed is always necessary—it’s just that it has to work over a narrower range, so a simple hole does the job. And that’s that, as they say.

So, next time you crack open that throttle, as you rush towards the horizon, that sweet motor music building towards its crescendo, spare a thought for all the elemental instruments harmonizing within your humble Keihin, or Shorty or Mikuni or whatever. Each effect is playing its part separately, but blending together in a century-old symphony—all without a computer in sight. Is that clever or what?