It’s no secret that production specs for the Harley-Davidson LiveWire show a substantial increase in range-per-charge over the prototypes seen a few years ago. And, that the best tech show on earth at the moment has to do with battery technology for EVs – mostly four-wheeled ones. Knowing that H-D’s “Connect” system of rider/motorcycle interface is from Panasonic, and Panasonic also supplies battery cells to Tesla, it’s fair to assume that H-D and Tesla use the same Lithium Ion technology if not the same suppliers (H-D likes Samsung). Here’s what this most likely means.

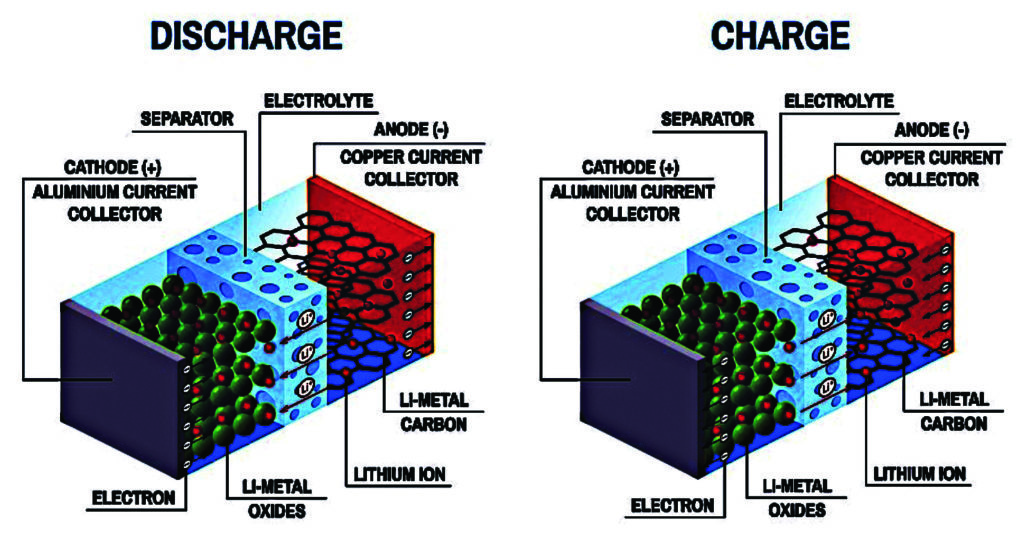

All batteries of any type since Volta in 1799 operate via current flow through electrolyte from anode (+) to cathode (-) and vice-versa through a separation barrier of some sort. Flow in one direction is charging, the other discharging. (See the diagram for graphic details.) The problem, then as now, is the damage the little guys – known as electrons – do as they crash into each other. Each crash decreases the effectiveness and the life of a battery because the electrons finally cease to get a charge out of it, winding up beaten to death. The challenge in battery tech as applied to everything in our battery-dependent culture, from hearing aids to electric vehicles and virtually everything in between, is to reduce and/or eliminate this pesky crashing.

Here’s what happens, and why charging and discharging are critical factors in Lithium Ion battery life. Electrons shouldn’t die young, and if they don’t the battery should last at least as long as the motorcycle. (Jay Leno’s 1908 Baker Electric car still takes a charge…think about it.)

Eliminating it would amount to a whole new operating system for batteries, the breakthrough, the revolution the world has been waiting for for three centuries. Reduction, on the other hand is the current (pardon the pun) battleground. Its best-known warrior (among many) is Lithium Ion. Created by Sony in the early ’90s and continuously refined since, LI is the best we’ve got – the major enabler of devices we can’t live without, from smartphones to power tools and a whole lot more. As is self-evident at this point, LI also plays a huge role in the advent – now onslaught – of electric vehicles, including the LiveWire. This, however, is where it gets to be heavy lifting for Lithium Ion, literally and figuratively.

When Tesla got rolling, the state-of-the-art LI cell, from which battery packs were built, was the 18650. Named for its dimensions, 18mm wide and 65mm tall, these cylindrical units (hence the zero) look like a flashlight battery. A few, packaged together, powered laptops. It’s what was available, so the first Tesla was essentially powered by laptop batteries. Sure enough, the specifics of the cell had to be tailored. After all, booting up and barreling along require different energy supply characteristics, as do the 18650’s other common high-load applications such as cordless power tools.

Panasonic and Tesla managed to wring every ounce of effective power the 18650 could manage in a few short years of development. But shortcomings loomed large as the limits approached. The short list amounts to being able to go fast but not far, charge times, heat, battery life and cost. By the time Milwaukee entered the picture, the 18650 was all in, with no future in EVs.

Waiting on the next big thing in battery cells was part of the reason it took so long to bring the LiveWire (and other H-D E-bikes) to market. Well, the next big thing turned out to be a little bigger, as you can guess from its name, the 21700. But it’s a lot better, too. It figures, as it was developed by Panasonic for the Tesla Model 3. But its use in the LiveWire was natural, as well. Without going all techno-babble on ya, let’s just say the 21700 is dimensionally 20% larger but gives double the power, because it isn’t just bigger (50% by volume) it’s designed differently. It’s also likely that fewer of the 21700 cells are required per “pack,” which is a bonus, since the size of the LiveWire cell pack defines one of the built-in constraints of a motorcycle chassis. Certainly, it explains why the production LiveWire is notably quicker and its battery pack will last longer, charge more quickly, run cooler and have more range.

Skimming the surface of EV cell tech leads to an examination of that other devil in the details … charging. Specifically, speed and rate of charge. So we’re back to charging electrons. Most heat/damage-related issues with any battery come from improper charging rates especially once the battery hits about 80-85% of capacity. At that stage electron activity is frenetic and lethal (to the battery). Most solutions up to now have amounted to slowing the last stage of “smart” charging at that point. Works okay, but to get charging times on EV’s down to the time it takes to fill, say, the tank of a gas buggy requires some new thinking. It’s coming in the form of, for lack of a better way to say it, AI charging in pulses rather than a continuous flow. The basic goal is getting to 80 percent in minutes or even seconds, not hours. Ultimately, there will be more charging stations (especially at H-D dealers who sell the LiveWire), where EV “juicing” will be as easy and quick as conventional fuel stops. Home charging at 110v will remain the place to top off, and total cost of ownership over time will be less than gasoline powered vehicles.

The prediction is that in just a few years, EV battery cells and charging will be vastly more efficient, cheaper and culturally pervasive. In lockstep with all that progress will be (hopefully) a good bit more desirability. Until now, most electric vehicles have been subsidized and/or mandated to establish a market for them. As alluded last month in this column, one of the first of these real “desirables” is the LiveWire!

Realizing that EV technology is evolving as we watch, and just might be replaced altogether with the breakthrough we anxiously await, it seems to me that Harley-Davidson should cover its bet by leasing the battery pack so owners can upgrade if and as required along the way. Renault has done just that with the 100,000-plus EVs they sold in France. Surprise! Their 22Kw power units initially supplied are being upgraded to the latest 44Kw versions, which make happy customers with higher resale values, just to name two benefits of the concept.

Until then, there a couple other things you might appreciate seeing as options, accessories or maybe hacks for H-D EVs. How about a backpack or tank bag incorporating a charge port plug and some extra battery capacity for emergencies? I’m also sure H-D has good reason to limit the LiveWire to a 90-something-mph top speed, but geez … somebody, somewhere, has to know how to defeat the limiter and give owners 10-20% more zoom. Right?