The luckiest Sportster ever

The staff XL gets the CR treatment

There are projects you undertake with a great deal of forethought and anticipation, and then there are projects that just sort of invent themselves and draw you in. This deal is of the latter variety, and started innocently enough with the procuring of a 2006 Sportster XL883L for the professional and recreational use of Thunder Press staff—you know, a bare-boned bargain-priced Sporty for weekend run coverage and basic spanking around the Santa Cruz Mountains and cruising the Pacific coastline for the soul-restorative therapy of getting the knees in the breeze. The fact that this year marks the 50th anniversary of the introduction of the XL gave the notion some added poignancy, and the fact that this wasn’t really a formal project bike, and thus wouldn’t place any particular demands on the overextended editor, was a particularly attractive selling point for the acquisition.

That notion lasted all of about a week. Like many of you, I’m helpless to let a stock Harley remain that way for long, and the more I looked at this bike, the more it revealed its inner longing to be something special, and reluctantly I began to consider upgrades. The first instinct, considering the limited experience of some of the folks who would be riding it, and considering what the bike would generally be used for, was to morph it into a modest day-tourer with practical accessories like crash bars, a sensible windscreen, and some sort of utilitarian saddlebags. That seemed a reasonable approach, and had the added advantage of not placing much in the way of the aforementioned demands on the overpiled plate of the aforementioned editor.

That notion unraveled pretty quickly also, due in large measure to an encounter with Charlie Stewart of BilletBoys.com and RC Cycles. When casually told of the bone-stock XL, Charlie said the one word that would prove my undoing.

“Akront,” he said. “The bike needs some Akront rims.”

The mention of that word sent my mind reeling back over 30 years; back to the days of café racers and the ABCs of the breed—i.e. Akront, Brembo, Ceriani. In almost the same instant I realized what had to happen to this XL. See, this year is not just the 50th anniversary of the Sportster, it’s the 30th anniversary of the ’77 XLCR—Willy G’s wildly unorthodox exercise in café styling, and bar-none the sexiest model to ever sport the Bar & Shield. The Motor Company didn’t see fit to commemorate that magnificent beast with an anniversary edition this year, but that didn’t mean we couldn’t, and thus began Project Hot Java.

We’d need to lay down some ground rules, though, since the idea wasn’t to recreate the ’77 XLCR, it was to apply the basic philosophy of the café racer to this bike, and in so doing, achieve two principle objectives: 1) Make it perform better than stock in every operational category, and: 2) Make it sexy as hell. No part would be added that didn’t offer an improvement in operational ease, safety or satisfaction, but by the same token, no part would be added—no matter how functional—that didn’t markedly enhance the bike’s visual appeal.

That may seem like a tall order on the face of it, but it hasn’t turned out to be much of an effort at all. It’s helped in the early stages of this project that RC Cycles shares that philosophy of bike building, and has the parts to prove it, sold under the BilletBoys.com banner.

The Akront rims came first, and a short history of the brand is in order here, since many who are new to this lifestyle don’t have the same hushed reverence for the things that most veteran riders do. From the 1960s until late in the 1990s, Akront was the premiere name in motorcycle rims and the choice of virtually all serious riders, whether on the street, on the track or in the dirt. They were also favored by American custom builders for their rugged beauty, and were especially prized by European road riders who considered them absolutely de rigueur on any self-respecting café racer. Sadly, that era ended badly when mismanagement, legal entanglements and labor strife led to the messy demise of the company nearly a decade ago. The name and proprietary engineering were salvaged some time later by another Spanish company, Morad, who set about restoring the brand to its former glory. As a result, Akront is once again among the premiere names in the industry. Six years ago, RC Cycles secured exclusive North American distribution rights to the Akront-Morad product line.

The Akront rims are available in four different profiles for various applications, and are carried in a wide variety of sizes from 16 x 5.50 to 21 x 2.15. They’re inventoried in polished and chrome finishes, and RC Cycles offers a full palette of anodized or powder-coated colors by special order. For this project, Charlie had a set of the popular MTR profile rims powder-coated black by Maas Brothers Metal Finishing in Livermore, California, along with a pair of Billet Boys CNC-machined 7075 billet aluminum hubs. Those components got laced together with polished stainless steel spokes, and we now had the gnarliest and coolest set of laced wheels going. So cool, in fact, that Charlie got concerned. He was subtle about it. He said something to the effect of, “With those ugly stock brake rotors on the bike, these wheels are sort of a waste, don’t you think?”

What to do? We didn’t necessarily want to change to a whole new brake system—though Brembos naturally occurred to us—since the Nissin calipers that come stock on the XL are excellent units, but we also didn’t want to violate our ground rules by sticking on just any rotors for the sake of looks unless they also offered some significant performance advantage. That prompted a call to Paul Kittrell at Lyndall Racing Brakes who responded by suggesting a pair of the company’s incredible new Apex composition rotors. These rotors are unlike anything else on the market, both in appearance and performance and that’s due in large part to the materials and process used to make the friction rings. Called “metal matrix composite,” the material is a blend of aluminum alloy and ceramic particles which is dramatically lighter than steel or cast iron, and capable of dissipating heat much more efficiently. But what’s more, the process Lyndall uses to create the composite concentrates the ceramic particles—which are what give the lightweight aluminum alloy sufficient wear-resistance and durability for hard use in brake applications—at the outermost portion of the friction ring. Fully 50 percent of the ceramic is found out there where the heat build-up is most severe, while only 15 percent is embedded towards the center where the temperature’s coolest. Aside from the obvious benefit of preventing wear where it’s most likely to occur, that distribution of the ceramic serves also to balance stresses resulting from that heat differential, thus minimizing distortion across the rotor.

The Apex rotors consist of three components: the friction ring, titanium button fasteners, and a 6061 aluminum carrier. The carriers are offered in three custom designs and in black, nickel or chrome finish. The friction rings come in either black or chrome, and the buttons come in black, silver, gold, red or blue. You can mix and match the components as you see fit to suit your bike’s cosmetics, and we opted for Arc carriers and a black/chrome/nickel color scheme to complement the Akront/Billet Boys wheels. The resulting units are positively gorgeous and, more importantly for our purposes, weigh in at an incredible two pounds each.

While the Apex rotors were in the works at Lyndall, Charlie realized another inconvenient truth which he expressed with his signature subtlety, saying something to the effect of: “Sure is a shame to have those wheels and rotors keeping company with that plain Jane stock pulley, don’t you think?”

Sigh. More work for the editor, it suddenly seemed; sacrificing sleep to comb red-eyed through the aftermarket catalogues looking for something suitably handsome, but not a pure fashion exercise, and something that would bolt up to a Sportster. That’s a tough call, but Charlie then came up with an elegant solution to the aesthetic quandary, noting that the recently introduced Nightster had a really bitchin’ black and satin pulley that would look killer without being ostentatious like a billet tribal buzz saw blade, and I contacted H-D to see if we could get our hands on one. The answer was that we could—that as soon as they were available in OE parts inventory they’d hook us up with one. Problem seemingly solved.

Time passes, and the XL sits on a lift at the RC Cycles shop in Danville patiently awaiting its makeover procedures while the Thunder Press staffers grow restless and disillusioned about a bike that was intended to be the spunky office Spankster and is suddenly seeming more like the editor’s folly. But finally, thankfully, the day arrives at last when all the ducks appear to be in a row—the wheels and rotors assembled and exquisitely finished and ready to mount, the Lyndall Red-Plus brake pads required for the Apex composite rotors are sitting on the workbench, and the Nightster pulley coming in the door fresh off the UPS truck. And the whole project starts off swimmingly, only to founder on the ’07 Nightster pulley, which, it turns out, is not a direct replacement for the pulley on the ’06 XL. It’s got one more tooth. But nobody knows this, and that’s not the type of difference you notice until you’ve gotten it installed and try to replace the drive belt. And even then it’s not obvious. By the time the whole confusing situation has been understood, a lot of colorful language has been spoken.

We’re at an impasse until Bob Gomes, the lead mechanic on the deal at this point, suggests giving the stock pulley the Nightster treatment, masking the perimeter band and shooting the rest of the thing flat black.

And that’s what he does, and it’s a convincing fake of a Nightster pulley, and a few days later the wheels are on, the rotors are on, and the pulley is on and all is right with the world until it’s time to install the brake pads, and it’s discovered that we have a set of Red-Plus pads for the Big Twin Hayes calipers, not the XL’s Nissin units. The stock pads can’t be used on the composite rotors, so more colorful language ensues and another stretch of waiting since Lyndall’s out of stock on the correct pads, and a new batch won’t be finished for a week. Sigh.

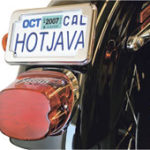

The extended downtime during this project was not wasted, however, since our man Charlie—who was proving to be both the angel on one shoulder and the devil on the other—had some other ideas about what this XL needed, starting with a Billet Boys LED tail/brake light with a lay-down lens profile. This light is dramatically brighter, faster responding, and more durable than the stock bulb, and thus was easy to justify under our function-first philosophy as a valuable safety feature. The lay-down lens profile also fulfilled our sexiness criterion, so this upgrade was a winner. And then Charlie had a Billet Boys lay-down chrome billet license plate frame installed, and it’s a super clean act and a real beauty, but I now had to figure out how this was anything more than a pure bling accessory and thus anathema to our project objective. I thought and thought. And then it came to me in: The lay-down frame is, in fact, another truly valuable safety feature in that you’re less likely to whack your shin on it when throwing a leg over the bike, which is always a hazard with the stock frame. How’s that for creative rationalization?

When the correct brake pads had arrived and been installed the first chapter of the project was a fait accompli and we went to fetch the XL—which was now no longer merely “the XL.” It had been elegantly transformed into Hot Java, sporting the lightest, strongest, safest, most café race-ready wheels and brakes ever mounted on an 883, and looking like a real hottie. Now to get this thing home and give the Thunder Press staffers—who long ago went from patient to disgruntled—a crack at piling some miles on this baby, and get them off my damn case about the whole deal.

But wait. Not so fast. Our man Charlie, the angel/devil, has yet another big idea; something to the effect of: “This bike needs a pair of billet grips, don’t you think?”

OK, this is where I draw the line. I hear “billet grips” and all I can think of is the least functional accessory ever invented; solid blocks of cushionless chrome-plated vanity; pure fashion statements with no redeeming operational value and miserably uncomfortable to boot. But Charlie’s unfazed by my attitude and insists on showing me the Billet Boys billet grips, and he does and I suddenly feel like a fool. They’re magnificent. They’re billet aluminum, all right, but they also incorporate Renthal grip rubber—the finest composition available and the gold standard among competitive motorcyclists on the track and in the dirt. And what’s more, these billet grips are offered in several finishes, and the satin black powder coat is ideal for Hot Java’s look. So master wrench Pat McNulty does a whiz-bang install of the grips before the bike goes out the door, and they’re nothing short of awesome, both in appearance and feel.

And that’s it for this installment of Project Hot Java. The bike’s next makeover session will involve air cleaner and exhaust upgrades, and then we’ll do suspension and tires. And lastly, we’ll see if we can’t find a really sexy cafe fairing to finish it off. That’s all assuming, of course, that the Thunder Press staff ever lets me near the bike again.

Resources:

RC Cycles

30872 Huntwood Avenue

Hayward, California

510.471.9755

175 Hartz Avenue

Danville, California

925.362.8220

www.rccycle.com

Billet Boys

510.471.3026

BilletBoys.com

Lyndall Racing Brakes

800.400.9490

www.lyndallracingbrakes.com

Maas Brothers Metal Finishing

285 South Vasco Road

Livermore, California

877.369.8200

www.maasbrothersinc.com