Perhaps you’ve heard that Harley-Davidson has discontinued all Screamin’ Eagle spark plugs. Perhaps you aren’t familiar with the importance of spark plugs. Perhaps you could care less. Perhaps you are grossly indifferent to the well-being of your mechanical steed. Perhaps your hog should have you horsewhipped!

Look, it seems simple, this spark plug thing. I’ll admit that. Yet, it’s not something that should fly beneath your radar, when it comes to caring for your engine. I’ll try to make the importance of your choice a little clearer, but you’ll have to bear with me until I can plow through some of the whatzit’s and wherefores to get at the bottom line.

First of all, in modern, fuel-injected Harley-Davidson engines, spark plugs have several crucial tasks to perform. The primary one is igniting the air/ fuel mixture, but it also functions as a “knock sensor” to protect the engine mechanically, and—for lack of a better way to put it—acts as a “temperature control valve.” When you stop to think about it, all three of these wagons circle around to battle a central and common foe—heat!

Second, we tend to labor under the false premise that our old air-cooled relics are fighting that battle with one hand tied behind their aluminum-finned back. After all, water-cooled stuff like V-Rods, Buell 1125Rs and most all other street bikes these days are pretty much immune to overheating, right? Guess again! What it comes down to is this: Water-cooled engines simply play at higher levels of power and therefore generate more heat, thus crowding the same thermal limits as an air-cooled hog. This fact is often expressed in “horsepower per liter” in the wider world that’s largely metric. You could do it in cubic inches as well, if that’s easier.

There’s also the rather comforting aspect of Iridium that promises to dissipate heat better. In fact it’s doubtful that any Harley with a license plate can get hot enough to destroy these spark plugs. Run some that are cool enough to keep you from destroying the engine and you’ll be better off in the long run

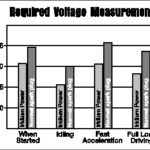

One interesting characteristic of spark plugs is they require more voltage to fire as they wear. Considering that iridium plugs require notably less voltage in the first place and in some cases will last as long as the engine they are used in, it sorta redefines the notion of normal wear and tear, doesn’t it?

For instance, many 600cc crotch rockets make 100 hp these days. That’s 1.66 hp per liter. A 1000cc four-banger that efficient would be making 160 hp (more than my car, fer krissakes) and generate humongous heat. On the other hand, a really well assembled specimen of Harley’s 1584cc Twinkie engine makes maybe 70 hp, which is more like 0.44 hp per liter. Roughly translated into temperature, it works like this: HPx0.746 = BTUh. So the Harley generates a little more heat than, say, a propane patio heater (46,000 BTUs) at about 52,200 BTUh. However, that’s not extreme for the sheer volume of air and metal that heat can dissipate into on a 96 c.i. twin cylinder engine. The little four-banger less than half that size is producing nearly 75,000 BTUh’s of heat, with far less mechanical opportunity to shed it into four tiny combustion chambers presenting not nearly as much available material for a heat sink. Can you see the need for adding cooling medium (like water and anti-freeze) here? Well, given that this cooling system is well-designed, it seems sane enough to conclude that wetter is better when it comes to controlling heat as a by-product of combustion. But what really happens is that the designers of high-performance motorcycle engines simply crank up the power output until it crowds (and sometimes crosses) the heat-failure threshold as often as air-cooled stuff! Well, at least when comparing stock engine to stock engine.

As you can imagine, things change substantially when you increase power. An easily achievable 30 percent increase in output on a Harley also means at least a commensurate increase in heat output. So, suddenly that air-cooled hog engine has as much heat to shed as the little sportbike, but no liquid coolant with which to do it. Hopefully, faithful readers of this column know by now that counting on various notions about keeping the oil cooler to resolve the situation is not the road to paradise. Not that it doesn’t help—it’s simply not a complete solution. Using lubricants that can better withstand the increases in heat is only a partial panacea as well. Hot (in both senses) Harley motors should obviously be treated to any and all of these heat management assists. However, it might help more to know more about the true nature of the mischief that too much temperature retention wreaks on metals in the machine.

Heat flow is proportional to the temperature difference across whatever is transmitting it. As long as the heat can pass through the metals in the motor, the interior temperatures don’t rise high enough to cause problems with detonation or lubrication. When engines start producing more power (crowding their design limits in many cases), the increase in “waste” heat as a by-product can saturate the materials in the engine and push temperatures past the limits on the hot side of the heads and cylinders. Even if the limits are not passed, they get crowded real hard and no part, inside or out, is free from the formidable stresses this creates.

Mind you, this stress is not exclusive to hopped-up engines, but is just more pronounced in them. New motors need careful break-in precisely because these sources of stress can come from the original heat treatment of the parts, or maybe head bolt load, or mostly because the exhaust side of the head runs so much hotter than the intake side. No matter! The point is, when the metal gets hot, nowhere near melting, but just on the close side of 500-600 degrees—well—shit definitely happens! Namely, a phenomenon known as “creep” (no relation to Eddie Haskell) from which no part in the engine is immune. (If it’s easier to picture it in your mind as “shape-shifting,” then call it that, because in essence that’s exactly what happens.) Seemingly solid materials get all plasticy and distorted and in extreme instances fail.

Among the first victims are those parts that work under the most extreme temps like valve seats, which might go oval-shaped or even tilt; guides which can shift, loosen, stick or worse; and distortion of the valves themselves. What was a beautiful full-circle contact with the seat, necessary by the way, for heat transfer out of the combustion chamber, now becomes a light touch at too few points in the circumference. The valves leak, and temperature goes up—a vicious circle— leading to premature wear and imminent failure, that is, if heat at this point cannot be better controlled.

Things aren’t much better for the other critical seal in the engine—the piston rings. Again, increased heat softens the piston, forcing the metal in the top ring to land down onto the compression ring itself. It sticks and the seal is destroyed. Hot combustion gases (intensified by the over-heated piston and the loss of its cooling path, the compression ring) now attack the second ring. If it goes, hot gasses blow down between the piston and the cylinder wall, sometimes even through the oil drain holes behind the oil ring, and burn to the point of seizure! This is the end result of an unchecked, out-of-control chain of warped, softened metals, trapped distorted rings, and burnt lubricant. All this is because parts in the engine lose (or alter) designed-in and vitally-important mechanical means of eliminating combustion heat.

There’s just not a lot you can do to correct the mechanicals involved, either. I mean, what are you gonna try—adding extra fins to the head? Cutting grooves for extra piston rings, maybe? Boost the piston oilers up to fire hose pressures? Sorry, not feasible! The fact is, just about the only easily-variable mechanical means that we can use to assist in the dissipation of this unwanted byproduct of combustion is the one we never think about.

What about just “plugging” the heat? Spark plugs come in different heat ranges. There is a reason for this. All the same, I know of way too many high-potency V-twins out there employing the standard spark plug. By “standard” I mean heat range, by the way. Sure, there are plenty of spark plugs on the market that offer trick alloys, specialized firing tips, unique designs and other features that mean those plugs are anything but standard, in that sense of the word. Exotic might even be the better term for some of these offerings. But, let’s get real for just moment and try to determine what works—and what doesn’t—in the first place. Then we can move on to how to choose the proper spark plug to help conduct heat out of your engine.

Actually, almost all recommended spark plugs for H-D engines work, at least in the sense that you can screw them into the heads and expect the motor to start and run. The question becomes, “for how long and how well?” Make no mistake, all spark plugs are not created equal. It’s more or less an open secret that Champion makes the standard spark plugs that wear the Harley-Davidson label. Of completely conventional construction, these plugs have the ubiquitous copper core, porcelain insulator, zinc-coated metal shell, regular-style(s) of side electrode and a ground electrode about the size of a pencil lead. Sufficient, perhaps—but hardly superior.

Debate rages over practically every aspect of spark plug design and construction—save one—and that has to do mostly with the size of the ground electrode. All experts agree, for performance work and increasingly even for normal applications, a fine wire electrode will provide a stronger spark from the existing voltage. (Logically, this is because the center electrode should work like the tip of a lightning rod, not the entire roof of your house, so to speak.) A couple of points about this point: Gone are the days when stock H-D ignition systems do not offer ample voltage. Older models could clearly benefit from upgraded coils and wires, but the new stuff gets along fine with what it has. Additionally, fine wire electrodes are nothing new. Getting them to survive in modified motors, let alone live long and prosper in a stocker, has been a different issue… until lately. Before we move on, I want to make it clear that no spark plug can (or will) overcome stupid owner tricks like poor tuning techniques and/or over-use of the enrichener/choke on carbureted bikes. Neglecting proper maintenance is another problem child, but for our purpose here, let’s just leave it with this guideline—if your stock spark plug will serve for 5,000 miles or so, you cannot help but benefit from a switch to the latest in fine wire spark plug technology: Iridium!

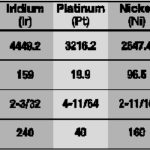

The advent of platinum-tipped plugs in the early ’80s was a step forward, especially compared to nickel alloy plugs of the day. All the same, iridium alloy (composed primarily of iridium, with rhodium mixed in for oxidation wear) is far superior to platinum based on hardness, strength and melting point. It has a melting point almost 700ºC higher than platinum and the greatest potential for resistance against wear. The thing is, the damn things will spark even with 5kv less energy from the coil! So, what we have is a spark plug using patented technology that ensures it will fire easier than any other, last longer than any other and take more heat than any other—by a huge margin! That adds up to a golden opportunity to use those characteristics to suck the heat out of our cylinder heads! See, historically, the only problem with so-called “cold” spark plugs was that they might foul. Any damn fool will realize that this a mere inconvenience compared to using “hot” plugs that might make all the excessive heat conditions (and outcomes) we just talked about worse! You wanna carry extra plugs, or rebuild engines? Well, thanks to iridium you probably won’t even have to carry the spares, since they are much less likely to foul if you want to drop a heat range or two. Why should you? Simple—the difference from one full heat range to the next is the ability to remove as much as 70°C to 100°C (212° Fahrenheit) from the combustion chamber! Nothing else you can do could make this much difference in the control of heat from the hottest spot in your engine, period! Switching to a colder plug should be automatic every time you increase engine output, and considered even if you just intend to use a stock (emissions-strangled) engine. Welcome to the 21st century!

Lastly, in case you wonder if I walk the walk or just talk the talk—I run spark plugs two heat ranges colder than stock in my own hopped-up (and carbureted) engine, yet haven’t puked one yet! Have I got your attention now? Look, think it over, do your own research and then give it try. After all, we know that in the end, cooler heads prevail. I only hope that the creative “spark” at The Motor Company results in iridium Screamin’ Eagle spark plugs when they are re-introduced.