It’s no secret there are plenty of choices for H-D exhaust systems; maybe too many. How the hell does anyone who actually cares about getting one that works, rather than one that is, as Shakespeare put it, “full of sound and fury, signifying nothing,” go about it?

Well, believe it or not, there are some basic guidelines. Not that they are simple to understand (lots of nasty math) or guaranteed to get you the results you crave, but it’s better than simply shooting from the hip or buying what your buddies have for lack of a better idea.

As I mentioned before, one size does not fit all, yet it amazes me that most manufacturers of so-called performance exhaust systems don’t bother to take that into account. Among the notable exceptions is D&D out of Texas, which offers not just the Fat Cat for most of us, but the Boarzilla as well, for the rare monster motor that needs more than regular systems are capable of. They have plenty of dyno time on their products as well, so rather than take it on faith or word of mouth, you can rest assured these pipes work better than most store-bought choices.

Of course, the most fanatical performance addicts will probably resort to building an exhaust instead of buying one off the shelf, but even those guys need to do more than just cobble something together and dyno the dog-crap out of it to truly dial in their creation. The majority of that minority will also resort, more often than not, to two individual tubes, one for each cylinder and aimed towards good ETs at a drag strip. Starting off with simple pipes that are too long, it becomes a tuning process that comes down to cutting an inch off at a time until the motor makes its best peak power.

There’s no doubt that for street riders or even road racers, there’s a huge difference between peak power and peak performance. They are emphatically not the same thing! Fundamentally, it comes down to tailoring and expanding the range of engine revolutions that will provide forward thrust whenever for whatever; in other words, a power band! Let me digress just a bit to make the point a little more relevant.

Once upon a time, cars did not have automatic transmissions. Most folks didn’t like to shift gears then, any more than they do now. Drag racing hadn’t really caught on, and quarter-mile times were not a part of the definition of performance in those days. Neither was peak horsepower. What mattered then was flexibility! People in those days were much more impressed with cars that would allow them to travel, say, anywhere from 4 mph to 104 mph—in top gear only—than with any of the more useless criteria we’ve had beat into us by magazines and advertising since then. I mean, what real good does it do us to know that our sled of choice, whether two wheels or four, will do a “published” 0–60 mph in “X” and a fraction of seconds? And, how often have you been to the drag strip lately to see if you can match or beat that quarter-mile ET on the printed page of your favorite magazine? Harsh reality is still more like it was for our forbearers, where flexibility, torque and a broad range of power—for climbing hills, passing or hauling payload—serves us best. Yeah, I know most modern Harleys have six speeds to choose from, but they got along nicely for decades with fewer choices. Peaky two-strokes and little bitty four-bangers might need all those gears, but H-Ds don’t—or shouldn’t—to give their best. Our big V-Twin engines still favor a big spread of power. For an example of what I’m driving at, as applied to Harley, try this: Leave a traffic light (with no traffic) in third or even fourth, and see what happens. The clutch might not like you for a day or two, but chances are your scooter will leave the light like a big tractor and pull to a pretty good speed before you need to shift. Neat! Nearly impossible with sport bikes and such… So there!

Now, back to how a good exhaust pipe choice can enhance that concept, if you agree with it. (Drag racers and folks who just do this pipe thing because “loud pipes save lives” can read something else now.)

Like camshaft choices, no exhaust system option will give you best bottom-end torque and best peak power. That said, some folks are trying. In the car world, a notable example is the Corvette, which offers exhaust options like an H-pipe or an X-pipe (crossover to us) as well as electronically controlled baffles that keep things quiet when they should be, yet reduce the restriction (and increase the noise) when it’s time to get it on. We aren’t quite there with exhausts for our hogs, but I predict we will be within the next decade. Until then, any choice we make will, of necessity, be a compromise. Compromises are OK, but disasters aren’t. Many are the pipe choices that not only don’t improve power on your bike, but in fact “nut” it pretty badly! I know of at least one instance involving a V-Rod where the owner chose a pipe design by a well-known company (starts with a V) that was really more like something you’d see on an air-cooled Big Twin. Big mistake! The poor owner spent a fortune on the pipes, a tuning device and dyno time, only to end up with 20 percent less power than she had stock, and virtually no torque until three-quarter throttle. She maintained that was just fine because she loved the sound. I maintain she’ll love that sound precisely until the moment a stock V-Rod walks all over her in a roll-on or when she wants to pass a truck in a hurry.

Can you see what camp I’m in on this issue? Can you see where all this is leading?

Well, it leads to the basics, I guess. Broadly speaking, there are two types of H-D exhausts—those with individual pipes and those that converge into one where the muffler attaches. Yup! Not like you never heard it before, but a two-into-one is usually the best compromise for overall power. Long head pipes in either case tend to make better power at lower rpm ranges and short(er) ones do more at high engine speeds. Then there’s the issue of diameter. Built motors can usually benefit from a pipe that’s larger than the standard 1-3/4″. But it’s tricky, because the trick is to deal in area, not diameter as such. Even then, the area a pipe offers to an open exhaust valve has to balance with the size of the valve, when it opens (and how long), the temperatures at work and more, so it’s anything but (pardon the expression) a “blow out” in favor of fat pipes. One can over-pipe, just as one can over-carburate (even with fuel injection), as we’ll see.

Anti-reversion (literally: “against reversing”) technology is useful, if misunderstood, in this context. Reversion is, for our purposes, the “back-flush” into the combustion chamber at the end of an exhaust stroke. To simplify a bit, uncontrolled or excessive reversion can cost you power if it interferes with cylinder fill on the next cycle, or contaminates the fresh air/fuel charge with exhaust gasses left over from poor scavenging. So, another general rule is that a pipe that reduces reversion is better than one that doesn’t… period! Got all that basic, simple stuff? OK, now we get serious!

Fast-flow requires some slow thinking…

Remember the two waves that occur when the exhaust valve cracks open? One is sonic, and the other is a particle wave. Let’s call the second “exhaust gas velocity,” and work forward from the fact that optimal EGV is between 280 and 300 fps (feet per second). Less than that and you lose power and throttle response. Too much velocity leads to internal “wall” friction and pumping losses. This EGV perfection only occurs in a certain rpm band. For racing, that should be at or near redline for max power. For the typical street bike, it should occur much closer to the middle of the rev range for the best power band. Here’s how you figure it: (piston speed in feet per minute divided by 60) x (bore squared divided by pipe I.D. squared) = EGV.

Unless you have yours memorized, the way to figure piston speed (not engine speed) is to double your stroke, divide that by 12, and then multiply that number by your desired rpm, giving you piston speed in feet per minute (fpm). Then, divide that by 60 to get fps (feet per second) to complete the calculation. But let’s save some time (and a headache) and cut to the chase.

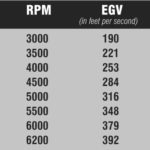

A 95″ Twinkie running 1-3/4″ (1.625″ I.D.) pipes will get EGV numbers like this:

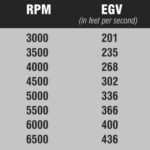

An 80″ EVO with the same thing:

See what I mean about one size not fitting all? On the Twinkie, 1-3/4″ pipes flow at the “ideal” (280–300 FPS) around 4,500 rpm. Those pipes on the Evo tend to operate well at more like 4,000 rpm. Neither engine, notably, does its best at the 3,000– 3,500 rpm “middle of the rev range” with standard diameter pipes, surprising in a way since most legal cruising velocities would typically be at these engine speeds, not the higher ones. Mostly, though, you notice extreme variations at either end of the respective rev-ranges for these two examples. Do the calculations for an 883 or an S&S 124, and the variations become even more pronounced. In my opinion, the main reason nobody bothers to do a more accurate job of sizing is:

“Regular” pipes do work within reason in the rpm ranges most of us actually use a lot;

Most folks don’t know any better in the first place; and

Where exactly does one find tubing in odd diameters?

See what I mean about compromises?

Right about here is where notions like cross-over pipes and stepped headers tend to come into play. They are mostly designed to fool the exhaust pulse into acting like it has those different diameters at different speeds and behaving accordingly.

We’ll see about that… (and a neglected player in this whole game that most people don’t ever deal with)… in the next episode!